Difference between revisions of "Talk:Equipment/Vinyl Cutter"

Joe Design (Talk | contribs) (→Vinyl cutter in producing accurate and safe etching of copper: new section) |

Joe Design (Talk | contribs) (→Have fun.) |

||

| Line 12: | Line 12: | ||

The salt solution can be used again and again after settling and decanting the copper oxide off.<br /> | The salt solution can be used again and again after settling and decanting the copper oxide off.<br /> | ||

===Have fun.=== | ===Have fun.=== | ||

| − | + | [[File:IMG_7072.jpg]]<br />[[File:IMG_7073.jpg]]<br />[[File:IMG_7074.jpg]] | |

Revision as of 15:19, 18 December 2017

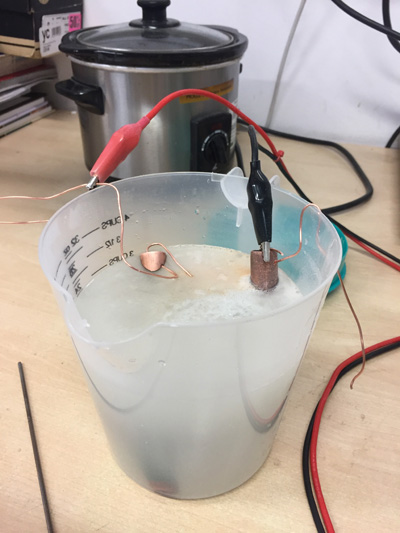

Vinyl cutter in producing accurate and safe etching of copper

Having cut and weeded the vinyl I applied it to cleaned and degreased copper. In this case, a copper plumbing pipe.

I applied the vinyl to the copper using the clear low tack tape to align the pattern.

I then removed the low tack tape and lowered the tube into my salt solution. This solution is made up of sea salt and warm water. You resolve the salt until it will not take any more salt, then remove excess salt from the bottom by decanting the solution.

Then I put another tube of the same size in the solution. Make sure these poles do not touch throughout the process

The anode from the charge circuit is connected to the piece to be etched. This is where the oxidisation will occur and the metal will give off electrons to the solution.

Then I connected the cathode to the other pipe.

A charge was then applied at around 2amps/2V for 20 minutes.

You will see bubbles at the cathode which will be hydrogen from the water and the solution will turn reddish brown.

The salt solution can be used again and again after settling and decanting the copper oxide off.