Difference between revisions of "Equipment/Screenprinting"

(→Equipment) |

m (→Summary) |

||

| (85 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| + | {{OrangeTool}} | ||

| + | |||

| + | [[File:Area_photo_20151222_thumb.jpg|right|Screenprinting area]] | ||

| + | |||

== Summary == | == Summary == | ||

| + | Screenprinting is a manual printing technique using liquid ink and a stencil to create permanent images on flat absorbent materials or items. | ||

| + | |||

| + | Typical materials to print onto include sheets of paper, card or fabric or pre-existing items such as t-shirts and cotton shopping bags. Due to the amount of work required for set-up before and clean-up after printing, the process is most suitable for printing multiple identical items in one session such as a set of t-shirts or posters. | ||

| + | |||

| + | A screen is a frame with a fine polyester mesh stretched across it which carries a stencil. The printing process applies liquid ink/paint in one colour at a time using a squeegee. The stencil on the screen-mesh works in a similar way to stencils in other art processes: some areas of the screen are left open and others are blocked. This determines where ink is deposited onto the piece and thus creates a design or image. The result is a thin film of ink applied to the workpiece. | ||

| + | |||

| + | Makespace supports non-photographic waterbased screenprinting on paper, fabric and other materials up to A2 size. | ||

| + | |||

| + | This is orange equipment because we recommended reading through these instructions before starting a session. This will improve the results you get and help us maintain the shared equipment through proper usage and cleaning. | ||

| + | |||

| + | Please read through the wiki and see Training below for videos and book available at Makespace. | ||

| + | |||

| + | === Making stencils === | ||

| + | There are many ways to create stencils, including cutting paper or sticky vinyl and also photographic emulsions. | ||

| + | At Makespace we support vinyl and paper stencils. Vinyl stencils can be made on the vinyl cutter. Paper stencils can be cut with scissors or craft knives or on the laser cutter, if you are already trained on it. | ||

| + | |||

| + | You will probably need to try different scales and types of stencil to work out which kind of stencil works best for your design. | ||

| + | Factors include the level of detail in the design and whether there are any 'islands' such as the inside of a letter 'o'. | ||

| + | |||

| + | Note: '''We do not currently support photographic methods at Makespace''' due to lack of a darkroom and lightsafe storage area. The current area is suitable for learning basic handprinting technique and smallscale craft and hobbyist printing. | ||

| + | |||

| + | It is possible to create photographic stencils at home and bring the finished screen in to print with at Makespace or to get a screen manufactured with your design. But please do not take Makespace screens away from Makespace. | ||

| + | |||

| + | Other dedicated print studios exist in Cambridge which do support photographic screenprinting process and open-access, for instance | ||

| + | [http://www.stbarnabaspress.co.uk/open-access.html St Barnabas Press] | ||

| + | |||

| + | === Main steps in the screenprinting process === | ||

| + | |||

| + | 0. If you are new to screenprinting, read the wiki, a book or watch the videos before starting a session. Once there is wet ink on the screen the actual printing should be done without any breaks to read instructions etc. or the ink will dry into the screen and damage it. | ||

| + | # Create a stencil and attach it to the screen (or use a screen with stencil prepared previously) [[CreatingScreenprintingStencils|more details]] | ||

| + | # Select or mix the appropriate ink for fabric or paper (by default a 50/50 mix of pigment/paint and print medium) | ||

| + | # Print things. More details for printing on [[ScreenprintingOnFabric|fabric]] and [[ScreenprintingOnPaper|paper/non-fabric]] | ||

| + | # Clean up: Reclaim ink where possible then clean screens and tools immediately. Wash ink from hands afterwards. | ||

| + | # Log prints done and materials used in the session in the log book. This helps the owners know which items are popular and to keep things in stock. | ||

| + | # Pay for any Makespace materials used (ink, all paper including test prints, cotton bags etc.) | ||

| + | # Fabric only: Once ink has dried, heat-fix any prints using the iron or heatpress | ||

| + | |||

| + | For more details follow the links above or see section on '''Training''' below. | ||

== Owners == | == Owners == | ||

* Jo Brook | * Jo Brook | ||

| − | |||

== Training == | == Training == | ||

See owners for occasional demos. | See owners for occasional demos. | ||

| + | |||

| + | [http://www.youtube.com/watch?v=ACgxOdNB8MI| Daler Rowney System 3 Screenprinting Demo (video)] | ||

| + | |||

| + | [http://www.instructables.com/id/Using-vinyl-stencil-to-silk-screen/?ALLSTEPS| Screenprinting with vinyl cutter stencil (instructions)] | ||

| + | |||

| + | Book: ''The Art Teacher's Guide to Water Based Screen Printing'' by Dave Fortune, kept in (and should always be returned to) the printing area. | ||

| + | |||

| + | ==Warnings== | ||

| + | Waterbased screenprinting does not have serious hazards as a process but without due care the ink can permanently damage various items in the space. This includes yours (or others') clothes or workpieces. | ||

| + | |||

| + | Take care when moving the larger and heavier pieces of equipment, especially if there are other people passing through the space. | ||

| + | |||

| + | ===Safety=== | ||

| + | * The main printbed and platen are solid and relatively heavy so take care when reversing the platen to or from t-shirt to flat-item-printing mode. | ||

| + | * The drawers in the plan chest are heavy and can be pulled all the way out of the chest. Be careful and pull them out slowly and not beyond around half way. | ||

| + | * After cleaning ink from the equipment also wash it off your hands and skin. If you print regularly the pigments in the ink may cause skin irritation if not removed. | ||

| + | * After washing up the equipment, ensure that the floor is not slippery by mopping up any water using the mops next to the sink. This is particularly important as the sink is on the busy main pathway through the space and to the secure workshop. | ||

| + | |||

| + | ===Care of personal items and shared equipment=== | ||

| + | * Screenprinting ink will stain clothes, since it is designed to dye fabric permanently. So wear an apron while printing and pay attention to stray bits of ink, wiping hands and equipment with tissue paper if needed during the session. | ||

| + | * Ink is liquid so work with care not to let splashes of it get onto other people's work. This applies especially when washing the screen out as the diluted ink can still stain and is more likely to splash than when the ink is in its print thickness. | ||

| + | * Wash out the screen immediately after the last item has been printed. There is a shower attachment which can be put onto the tap. Waterbased ink starts drying into the screen as soon as you are not actively printing to force new ink through the mesh. Dried-in acrylic ink forms a plastic material which cannot be washed out and which blocks the holes in the mesh, rendering the screen unusable. Prompt washout will help remove as much ink as possible which will help shared screens to be ready for the next user. | ||

== House Rules == | == House Rules == | ||

| − | + | ||

| − | + | The facilities are shared and the printing area is small and located in a busy area. So there are some house rules for using this equipment. | |

| − | * | + | |

| − | * | + | ===Ink / paint=== |

| − | * No permanent stencils should be applied to screens. | + | * Makespace supports waterbased printing only, whether you are using Makespace shared equipment or some of your own. |

| − | * | + | So, as a guide, do not use any inks, paints or varnishes which cannot be removed from the screen using just water and washing up liquid. (Non-waterbased printing is offered by some of the specialist printmaking studios in Cambridge.) |

| − | * For large print runs and longer-term use, we recommend buying or making your own | + | * You may bring in and use your own ink if it is waterbased. If it is not one of the inks already in stock, check the procedure for bringing chemical products into Makespace: [[Hazardous_Materials]]. Most suitable inks will be the ones which don't have hazard warnings. If in doubt about ink, ask the owners or on the forum before using it in Makespace. |

| − | + | ||

| + | ===Screens=== | ||

| + | Makespace has a small number of shared screens which are intended for short-term use and learning. | ||

| + | |||

| + | As they are shared this means that: | ||

| + | * No permanent stencils should be applied to screens. These are only usually needed for print runs in the 1000s of items. | ||

| + | * You should aim to finish your printing in one session if possible and remove the stencil at the end of the session. | ||

| + | * For large print runs and longer-term use, we recommend buying or making your own screen(s). | ||

== Equipment == | == Equipment == | ||

'''Screenprinting frame:''' | '''Screenprinting frame:''' | ||

| − | * Hinge clamps to hold | + | * Hinge clamps to hold screen during session |

| − | * | + | * Reversible bed with: |

| − | ** Hinged platen for printing larger t-shirts | + | ** Flat surface for printing onto paper and other single-layer materials and smaller items such as tote bags and t-shirts smaller than XL. |

| − | + | ** Hinged platen for printing larger (XL+) t-shirts (pull t-shirt over platen to stop ink printing through to the back layer) | |

| + | |||

'''Print-drying rack''' 20 spring-loaded A2 wire shelves | '''Print-drying rack''' 20 spring-loaded A2 wire shelves | ||

| − | '''Plan chest''' A1 primarily for storage of papers and | + | '''Plan chest''' A1 primarily for storage of papers, stock and temporary storage for personal screenrprinting projects. |

'''Screens''' | '''Screens''' | ||

| + | |||

outer w x h (max printable area w x h) | outer w x h (max printable area w x h) | ||

Thread-count: Approximately 28T | Thread-count: Approximately 28T | ||

| Line 40: | Line 112: | ||

'''Squeegees''' | '''Squeegees''' | ||

| + | Communal blank screens for use with temporary paper or vinyl stencils: | ||

| + | {| | ||

| + | |- | ||

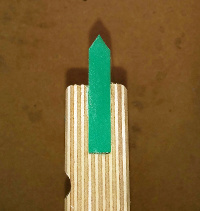

| + | | For textile printing D or V-profile blades are used. These blade profiles lay down extra ink which is used to get a solid print on the fabric surface as some is absorbed into the fibres: | ||

| + | *1 x 8" (20cm) width, V-profile blade | ||

| + | *1 x 12" (30.5cm) width, V-profile blade | ||

| + | *1 x 15" (38cm) width, round profile blade | ||

| + | | [[File:Squeegee blades vprofile.jpg|200px|right|alt text]] | ||

| + | |- | ||

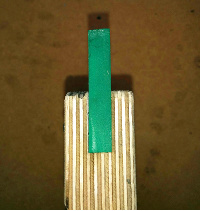

| + | | For printing on paper and other non-fabrics and less absorbent surfaces use square-profile blades which lay down less ink and give a sharper print: | ||

| + | *1 x 8" (20cm) width | ||

| + | *1 x 12" (30.5cm) width | ||

| + | | [[File:Squeegee blades squareprofile.jpg|200px|right|alt text]] | ||

| + | |} | ||

| − | + | *Makespace logo screens (2) | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | * | + | '''Washout''' |

| − | * | + | *Shower attachment for tap (kept in or under sink) |

| + | *Washing-up liquid (kept near sink) | ||

| + | *Scrubbing brushes | ||

'''Other small tools:''' | '''Other small tools:''' | ||

| Line 54: | Line 139: | ||

'''Protective clothing:''' | '''Protective clothing:''' | ||

| − | * Printer's aprons | + | * Printer's aprons |

| − | == | + | == Stock == |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

'''Supplies''' | '''Supplies''' | ||

| − | * Unprinted newsprint paper, A2 sheets ( | + | * Unprinted newsprint paper, A2+ sheets (50x70cm) |

For test printing and creation of paper stencils (using manual cutting or lasercutter) | For test printing and creation of paper stencils (using manual cutting or lasercutter) | ||

| − | This is not considered | + | This is not considered printing paper stock as it will yellow in sunlight and is thus not suited to making finished products |

* Washing-up liquid | * Washing-up liquid | ||

| − | + | '''Inks, pigments and mediums''' | |

| − | + | ||

| − | '''Inks | + | |

* System 3 Acrylic print medium (paper/general use) | * System 3 Acrylic print medium (paper/general use) | ||

* System 3 Acrylic print medium (fabric) | * System 3 Acrylic print medium (fabric) | ||

| − | * System 3 Acrylic pigments for colour mixing: Black, white, yellow, red, blue | + | * System 3 Acrylic pigments for colour mixing: Black, white, yellow, red, blue, silver |

| − | * | + | * Permaset Aqua Fabric Magic -- print-ready (pre-mixed) fabric inks: Black, green |

| + | |||

| + | '''Cotton Shopping Bags''' | ||

| + | *Arum 5oz fair trade natural cotton bag 42cm(h)x38cm(w), long handles | ||

| − | ''' | + | '''High-quality art paper''' |

| − | * A2+ 250gsm printing paper. | + | * A2+ 250gsm printing paper. £1.30 per sheet. |

| − | == | + | == Documents == |

| − | + | ||

| − | + | ||

| − | + | [[File:RiskAssessmentScreenprinting.pdf|Risk Assessment]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | [https://docs.google.com/document/d/126icVaL26e7uN-MAWLglC6a8GTyMyNR_htLq6toFI80/edit?usp=sharing Guide sheet] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | == Wishlist / Ongoing issues == | |

| − | + | ||

| − | + | ||

| − | * | + | '''Workbench, drying area and storage''' |

| − | + | * Vertical drying rack to store screens and keep them off the dusty floor | |

| + | e.g., like this at London Createspace: | ||

| + | [[File:Createspace screenrack.png]] | ||

| − | + | '''Photographic stencil creation''' | |

| − | + | ||

| − | + | After many discussions over the last few years we have decided we cannot run any kind of darkroom on the current site at Mill Lane due to many practical issues and the terms of our tenancy. | |

| − | * | + | In theory a screen-exposure darkroom would need: |

| − | + | * Mini-darkroom area for exposing screens -- could maybe be tent/pop-up | |

| + | * Lightsafe, undisturbed space/cupboard for storing multiple emulsion-coated screens overnight to dry -- cannot be pop-up | ||

| + | * Exposure unit or lamp. Photo-cube lamps could work if daylight colour-temperature (5000K) bulbs are replaced. | ||

Latest revision as of 18:57, 19 January 2020

Class Orange equipment: Only use if you are confident doing so. Training is available if not.

(More about equipment classes)

Contents

Summary

Screenprinting is a manual printing technique using liquid ink and a stencil to create permanent images on flat absorbent materials or items.

Typical materials to print onto include sheets of paper, card or fabric or pre-existing items such as t-shirts and cotton shopping bags. Due to the amount of work required for set-up before and clean-up after printing, the process is most suitable for printing multiple identical items in one session such as a set of t-shirts or posters.

A screen is a frame with a fine polyester mesh stretched across it which carries a stencil. The printing process applies liquid ink/paint in one colour at a time using a squeegee. The stencil on the screen-mesh works in a similar way to stencils in other art processes: some areas of the screen are left open and others are blocked. This determines where ink is deposited onto the piece and thus creates a design or image. The result is a thin film of ink applied to the workpiece.

Makespace supports non-photographic waterbased screenprinting on paper, fabric and other materials up to A2 size.

This is orange equipment because we recommended reading through these instructions before starting a session. This will improve the results you get and help us maintain the shared equipment through proper usage and cleaning.

Please read through the wiki and see Training below for videos and book available at Makespace.

Making stencils

There are many ways to create stencils, including cutting paper or sticky vinyl and also photographic emulsions. At Makespace we support vinyl and paper stencils. Vinyl stencils can be made on the vinyl cutter. Paper stencils can be cut with scissors or craft knives or on the laser cutter, if you are already trained on it.

You will probably need to try different scales and types of stencil to work out which kind of stencil works best for your design. Factors include the level of detail in the design and whether there are any 'islands' such as the inside of a letter 'o'.

Note: We do not currently support photographic methods at Makespace due to lack of a darkroom and lightsafe storage area. The current area is suitable for learning basic handprinting technique and smallscale craft and hobbyist printing.

It is possible to create photographic stencils at home and bring the finished screen in to print with at Makespace or to get a screen manufactured with your design. But please do not take Makespace screens away from Makespace.

Other dedicated print studios exist in Cambridge which do support photographic screenprinting process and open-access, for instance St Barnabas Press

Main steps in the screenprinting process

0. If you are new to screenprinting, read the wiki, a book or watch the videos before starting a session. Once there is wet ink on the screen the actual printing should be done without any breaks to read instructions etc. or the ink will dry into the screen and damage it.

- Create a stencil and attach it to the screen (or use a screen with stencil prepared previously) more details

- Select or mix the appropriate ink for fabric or paper (by default a 50/50 mix of pigment/paint and print medium)

- Print things. More details for printing on fabric and paper/non-fabric

- Clean up: Reclaim ink where possible then clean screens and tools immediately. Wash ink from hands afterwards.

- Log prints done and materials used in the session in the log book. This helps the owners know which items are popular and to keep things in stock.

- Pay for any Makespace materials used (ink, all paper including test prints, cotton bags etc.)

- Fabric only: Once ink has dried, heat-fix any prints using the iron or heatpress

For more details follow the links above or see section on Training below.

Owners

- Jo Brook

Training

See owners for occasional demos.

Daler Rowney System 3 Screenprinting Demo (video)

Screenprinting with vinyl cutter stencil (instructions)

Book: The Art Teacher's Guide to Water Based Screen Printing by Dave Fortune, kept in (and should always be returned to) the printing area.

Warnings

Waterbased screenprinting does not have serious hazards as a process but without due care the ink can permanently damage various items in the space. This includes yours (or others') clothes or workpieces.

Take care when moving the larger and heavier pieces of equipment, especially if there are other people passing through the space.

Safety

- The main printbed and platen are solid and relatively heavy so take care when reversing the platen to or from t-shirt to flat-item-printing mode.

- The drawers in the plan chest are heavy and can be pulled all the way out of the chest. Be careful and pull them out slowly and not beyond around half way.

- After cleaning ink from the equipment also wash it off your hands and skin. If you print regularly the pigments in the ink may cause skin irritation if not removed.

- After washing up the equipment, ensure that the floor is not slippery by mopping up any water using the mops next to the sink. This is particularly important as the sink is on the busy main pathway through the space and to the secure workshop.

- Screenprinting ink will stain clothes, since it is designed to dye fabric permanently. So wear an apron while printing and pay attention to stray bits of ink, wiping hands and equipment with tissue paper if needed during the session.

- Ink is liquid so work with care not to let splashes of it get onto other people's work. This applies especially when washing the screen out as the diluted ink can still stain and is more likely to splash than when the ink is in its print thickness.

- Wash out the screen immediately after the last item has been printed. There is a shower attachment which can be put onto the tap. Waterbased ink starts drying into the screen as soon as you are not actively printing to force new ink through the mesh. Dried-in acrylic ink forms a plastic material which cannot be washed out and which blocks the holes in the mesh, rendering the screen unusable. Prompt washout will help remove as much ink as possible which will help shared screens to be ready for the next user.

House Rules

The facilities are shared and the printing area is small and located in a busy area. So there are some house rules for using this equipment.

Ink / paint

- Makespace supports waterbased printing only, whether you are using Makespace shared equipment or some of your own.

So, as a guide, do not use any inks, paints or varnishes which cannot be removed from the screen using just water and washing up liquid. (Non-waterbased printing is offered by some of the specialist printmaking studios in Cambridge.)

- You may bring in and use your own ink if it is waterbased. If it is not one of the inks already in stock, check the procedure for bringing chemical products into Makespace: Hazardous_Materials. Most suitable inks will be the ones which don't have hazard warnings. If in doubt about ink, ask the owners or on the forum before using it in Makespace.

Screens

Makespace has a small number of shared screens which are intended for short-term use and learning.

As they are shared this means that:

- No permanent stencils should be applied to screens. These are only usually needed for print runs in the 1000s of items.

- You should aim to finish your printing in one session if possible and remove the stencil at the end of the session.

- For large print runs and longer-term use, we recommend buying or making your own screen(s).

Equipment

Screenprinting frame:

- Hinge clamps to hold screen during session

- Reversible bed with:

- Flat surface for printing onto paper and other single-layer materials and smaller items such as tote bags and t-shirts smaller than XL.

- Hinged platen for printing larger (XL+) t-shirts (pull t-shirt over platen to stop ink printing through to the back layer)

Print-drying rack 20 spring-loaded A2 wire shelves

Plan chest A1 primarily for storage of papers, stock and temporary storage for personal screenrprinting projects.

Screens

outer w x h (max printable area w x h) Thread-count: Approximately 28T

- 1 x 31cm x 32cm (21cm x 22cm)

- 2 x 45cm x 58cm (35cm x 48cm)

- 3 x 56cm x 77cm (40cm x 60cm)

Squeegees Communal blank screens for use with temporary paper or vinyl stencils:

For textile printing D or V-profile blades are used. These blade profiles lay down extra ink which is used to get a solid print on the fabric surface as some is absorbed into the fibres:

|

|

For printing on paper and other non-fabrics and less absorbent surfaces use square-profile blades which lay down less ink and give a sharper print:

|

- Makespace logo screens (2)

Washout

- Shower attachment for tap (kept in or under sink)

- Washing-up liquid (kept near sink)

- Scrubbing brushes

Other small tools:

- Palette knife (for transferring ink to/from the screen)

Protective clothing:

- Printer's aprons

Stock

Supplies

- Unprinted newsprint paper, A2+ sheets (50x70cm)

For test printing and creation of paper stencils (using manual cutting or lasercutter) This is not considered printing paper stock as it will yellow in sunlight and is thus not suited to making finished products

- Washing-up liquid

Inks, pigments and mediums

- System 3 Acrylic print medium (paper/general use)

- System 3 Acrylic print medium (fabric)

- System 3 Acrylic pigments for colour mixing: Black, white, yellow, red, blue, silver

- Permaset Aqua Fabric Magic -- print-ready (pre-mixed) fabric inks: Black, green

Cotton Shopping Bags

- Arum 5oz fair trade natural cotton bag 42cm(h)x38cm(w), long handles

High-quality art paper

- A2+ 250gsm printing paper. £1.30 per sheet.

Documents

File:RiskAssessmentScreenprinting.pdf

Wishlist / Ongoing issues

Workbench, drying area and storage

- Vertical drying rack to store screens and keep them off the dusty floor

e.g., like this at London Createspace:

Photographic stencil creation

After many discussions over the last few years we have decided we cannot run any kind of darkroom on the current site at Mill Lane due to many practical issues and the terms of our tenancy.

In theory a screen-exposure darkroom would need:

- Mini-darkroom area for exposing screens -- could maybe be tent/pop-up

- Lightsafe, undisturbed space/cupboard for storing multiple emulsion-coated screens overnight to dry -- cannot be pop-up

- Exposure unit or lamp. Photo-cube lamps could work if daylight colour-temperature (5000K) bulbs are replaced.