Difference between revisions of "Equipment/Laser Cutter"

(→Examples) |

(→Instructions) |

||

| Line 6: | Line 6: | ||

== Instructions == | == Instructions == | ||

| + | |||

| + | '''First draft to be expanded - please read the paper copy manual''' | ||

| + | |||

| + | '''The laser cutter must only be operated by members who have received appropriate training''' | ||

| + | |||

| + | '''Powering up''' | ||

| + | |||

| + | |||

| + | First give the machine a quick visual check. Make sure that there is nothing left on the bed and that the equipment has no obvious damage. Make sure the lid is closed. Turn the key on the right hand side to 'On'. This will set the cutter into doing its self-checks and also automatically start the cooling water feed pump. The air filtering system on the right hand side of the machine has its own 'on' button which should also be turned on. While the machine warms up power up the adjacent PC. This is running XP. The laser cutter application is obvious on the desktop. | ||

| + | |||

| + | |||

| + | '''Setting the focus''' | ||

| + | |||

| + | |||

| + | If the mirror adjustment has been completed the only adjustment on the machine is the height of the bed, and thus the work piece, from the lens. The critical dimension here is 41mm and several gauges made of perspex will be left around the machine. This gauge needs to be a fit between the top surface of the material you intend to cut and the white plastic 'flap' on the lens piece. Failure to set the distance correctly will result in an out of focus laser and much bigger (put lower powered) cut line. | ||

| + | |||

| + | |||

| + | '''loading your drawing''' | ||

| + | |||

| + | |||

| + | The PC software has an import facility which seems to be happy taking AutoCAD 2004 DXF files and other formats. The scaling seems to be a bit funny so drawing a known size rectangle around your drawing helps check it has things correct. If the import doesn't do what you want size-wise you can then select the whole image and the use the 'size' command from the drop down menu to set the dimension you want. Clicking on the three dots ... symbol will adjust the other axis in the same proportion. Selecting the 'centre on bed' option will locate your imported drawing on the centre of the machines cutting bed. | ||

| + | |||

| + | |||

| + | '''assigning actions to colours''' | ||

| + | |||

| + | |||

| + | Your drawing will show on the screen in various colours. Each colour will appear on the menu on the right hand side of the screen with numbers related to power and speed of the laser which will be used for the colour. The handbook provided with the machine gives suggested values for various materials but these should be considered as a starting point for a test. In due time we will try to build up a sample stock of materials and record the values which work best. For example the book suggested a speed of 10 for 3mm MDF which on one sample was so slow it burned a massively thick line, 40 ended up as a better speed. | ||

| + | |||

| + | |||

| + | '''Download the file to the cutter''' | ||

| + | |||

| + | |||

| + | The download option will by default call the file on the laser cutter 'LASER'. | ||

| + | |||

| + | |||

| + | '''Aligning the job on the cutter''' | ||

| + | |||

| + | |||

| + | Your drawing will feature a blue dot which represents the starting point of the laser, this is by default on the top right corner. The cutter's menu will show the most recent downloaded file highlighted. Pressing the 'test' button will make the head travel along the maximum extends of the cuts. This shows you that you have the material in the right place, and you have enough of it! You can do this repeatedly, opening the lid, moving the work place, closing the lid, test, until you have things where you want them. | ||

| + | |||

| + | |||

| + | '''cutting the work''' | ||

| + | |||

| + | |||

| + | When happy with the location of the material press 'start' to start the cutter. Watch the head and at least at first be prepared to press the 'stop' button immediately if you find you are burning massive holes in you work piece! This goes back to doing some tests on a sample of your material and making sure you are happy with the cut speeds and power you have selected. You should stay near the cutter at all times and be prepared to pause it or stop it in the event of fire. | ||

| + | |||

| + | '''DO NOT LEAVE THE CUTTER UNATTENDED''' | ||

| + | |||

| + | |||

| + | '''finishing''' | ||

| + | |||

| + | |||

| + | The end of the job is signified by a beep. Waiting a few moments for the exhaust pump to clear any remaining smoke is a good idea and will limit the build up of smells in the rest of the workshop. Remove your work piece, ensuring that all parts are cleared from the bed of the machine. | ||

| + | |||

| + | |||

| + | '''turning off''' | ||

| + | |||

| + | |||

| + | The cutter is turned off using the key switch, check that air filtering system is also turned off. Shut down the PC and double check that everything is left in save state for the next user. Go away excited by what you can make and come back with lots more drawings! | ||

== Health and Safety == | == Health and Safety == | ||

Revision as of 23:30, 14 January 2013

Contents

Summary

Training

Instructions

First draft to be expanded - please read the paper copy manual

The laser cutter must only be operated by members who have received appropriate training

Powering up

First give the machine a quick visual check. Make sure that there is nothing left on the bed and that the equipment has no obvious damage. Make sure the lid is closed. Turn the key on the right hand side to 'On'. This will set the cutter into doing its self-checks and also automatically start the cooling water feed pump. The air filtering system on the right hand side of the machine has its own 'on' button which should also be turned on. While the machine warms up power up the adjacent PC. This is running XP. The laser cutter application is obvious on the desktop.

Setting the focus

If the mirror adjustment has been completed the only adjustment on the machine is the height of the bed, and thus the work piece, from the lens. The critical dimension here is 41mm and several gauges made of perspex will be left around the machine. This gauge needs to be a fit between the top surface of the material you intend to cut and the white plastic 'flap' on the lens piece. Failure to set the distance correctly will result in an out of focus laser and much bigger (put lower powered) cut line.

loading your drawing

The PC software has an import facility which seems to be happy taking AutoCAD 2004 DXF files and other formats. The scaling seems to be a bit funny so drawing a known size rectangle around your drawing helps check it has things correct. If the import doesn't do what you want size-wise you can then select the whole image and the use the 'size' command from the drop down menu to set the dimension you want. Clicking on the three dots ... symbol will adjust the other axis in the same proportion. Selecting the 'centre on bed' option will locate your imported drawing on the centre of the machines cutting bed.

assigning actions to colours

Your drawing will show on the screen in various colours. Each colour will appear on the menu on the right hand side of the screen with numbers related to power and speed of the laser which will be used for the colour. The handbook provided with the machine gives suggested values for various materials but these should be considered as a starting point for a test. In due time we will try to build up a sample stock of materials and record the values which work best. For example the book suggested a speed of 10 for 3mm MDF which on one sample was so slow it burned a massively thick line, 40 ended up as a better speed.

Download the file to the cutter

The download option will by default call the file on the laser cutter 'LASER'.

Aligning the job on the cutter

Your drawing will feature a blue dot which represents the starting point of the laser, this is by default on the top right corner. The cutter's menu will show the most recent downloaded file highlighted. Pressing the 'test' button will make the head travel along the maximum extends of the cuts. This shows you that you have the material in the right place, and you have enough of it! You can do this repeatedly, opening the lid, moving the work place, closing the lid, test, until you have things where you want them.

cutting the work

When happy with the location of the material press 'start' to start the cutter. Watch the head and at least at first be prepared to press the 'stop' button immediately if you find you are burning massive holes in you work piece! This goes back to doing some tests on a sample of your material and making sure you are happy with the cut speeds and power you have selected. You should stay near the cutter at all times and be prepared to pause it or stop it in the event of fire.

DO NOT LEAVE THE CUTTER UNATTENDED

finishing

The end of the job is signified by a beep. Waiting a few moments for the exhaust pump to clear any remaining smoke is a good idea and will limit the build up of smells in the rest of the workshop. Remove your work piece, ensuring that all parts are cleared from the bed of the machine.

turning off

The cutter is turned off using the key switch, check that air filtering system is also turned off. Shut down the PC and double check that everything is left in save state for the next user. Go away excited by what you can make and come back with lots more drawings!

Health and Safety

Maintenance Schedule

Every Job (done by all laser users)

- Clean the laser bed with IPA and cloth

- Clean any debris off laser bed and surround using soft brush

Every Week (done by laser maintainers)

- Clean the laser lens with IPA and cotton buds

- Oil the 3 runners with 3-in-one light oil

- Thoroughly clean the laser bed with IPA and cloth

- Check the water level in the cooling tank

- Clean and remove debris from the machine base and catchment drawer

Every Month (done by laser maintainers)

- Check the water is clean in the cooling tank (i.e. no contamination/organic build up)

- Check filter unit for filter renewal

- Oil the 4 rise and fall lead screws with 3-in-one light oil

- Check mirrors and clean with a disposable sachet lens cleaner cloth (only if needed, mirror coatings are delicate)

- Work through mirror alignment procedure to check alignment of mirrors

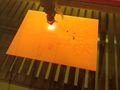

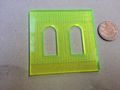

Examples

Examples of laser jobs we've run (please add a photo of yours any time you do a job!)

Shopping List

- 3-in-one light oil

- Cotton Buds

- Lens cleaner sachets

- Soft paint/cleaning brush

- Thermometer for water tank

- Hand held CO2 extinguisher

Information

Purchase and Repairs

Full Purchase, Delivery and Installation (£6865.00+vat = £8238.00)

- LS 6090 PRO Laser engraving and cutting machine, 600mm by 900mm 60W (£5250.00+vat)

- Laser Fume Filter (£1250.00+vat)

- Delivery (£190+vat)

- Installation/Training (£175+vat)

Maintenance and Spares:

- 60 watt C02 laser tube (£275.00+vat)

- 50 mm Focus Meniscus Lens (£75.00+vat)

- Estimate for Call Out (£200.00)

Whilst tube lifetime is impacted a lot by usage and care, we will initially estimate the need to replace the laser tube every 6 months

Install

Questions and Potential Requirements

- Cambridge Science Centre

- 600 x 900mm would allow use for exhibit units

- Thickness of materials?

- 25mm acrylic, 10-12mm ply (depending on ply)

- Do we need a cooler unit?

- No. More needed for continuous use (we expect regular but intermittent use)

- What are the power supply requirements?

- 240 V 50hz

--Brian Corteil 00:45, 3 January 2013 (UTC) How much power does the laser and the fume filter, require?

I have looked on their website and it's not clear, I also had a looked on the Bofa Website for information about the fume filter, and there are too many models to be able select the correct model. When you next contact the supplier. Can you ask the following.

What size supply will each item require?

I did read somewhere on the site, that the laser and the fume filter would be interlocked, is this correct? If so, this would suggest that only single supply would be required for both items. and one more question,

does the laser need a assigned PC?

- [User:Barhamd] I'm wanting to cut thin 1mm and .5mm ABS or perspex for model buildings. Would like something that can cut and half-cut a fine ~.25mm line. Not so concerned about massive size. Is this some kind of work something that could be done on a large cutter or do we need a smaller unit too?

- It states "Resetting position accuracy: 0.015mm"

- How often do the lasers need replacing?

- It depends on lots of things like care, use level, how much degradation is acceptable, luck - "could be 1 year or 5 years"; we will assume every year for now

- What (if anything) can this do on metals?

- What sort of line thickness does it give?

The bare minimum for me would be something capable of cutting an A3 sheet, which probably means 600x450mm. A 1200x900mm[1] machine from Laserscript comes in at about £6.5K; a used one went on eBay recently for something like £4.5K. The factory gate price for a similar unit from Shenhui, who are a well-regarded Chinese manufacturer, is $4K -sea-freight would come in at $250, and import duty appears to be 4.5%.

I (Dave from the science centre) would be really keen to be able to cut at least A1 on it (840x594mm) As this is the biggest module we are using at the moment.

Laser cutters used by other spaces, and other references

| Model | Owner | Cost | Bed size | URL |

|---|---|---|---|---|

| HPC LS3060 | London Hackspace | 3250 | 290x570 | http://hpclaser.co.uk/index.php?main_page=product_info&cPath=1&products_id=39 |

| HPC LS3020 | Nottinghack | 1125 | 300x210 | http://hpclaser.co.uk/index.php?main_page=product_info&cPath=1&products_id=40 |

| Epilog Mini 24 40W | FabLab Manchester | (Estimated) 11450 | 300x600 | http://www.epiloglaser.co.uk/legend_mini24.htm |

For comparison, a 1200x900 laser cutter from Shenhui (who appear to be the internet's Chinese supplier of choice) comes in at US$4000 + US$250 seafreight + 4.5% import duty + delivery (or collection) from Felixstowe - that's roughly £2775 ex VAT.

Replacement tubes cost £195 ex VAT for a 40W HPC tube (LS3020/LS3060) and £350 ex VAT for an 80W (LS1290). They are rated at 1000 hours, although this is heavily dependent on careful calibration of the machine and will be much lower if it's misconfigured.