Difference between revisions of "Equipment/VacuumFormer"

(→Further Information: Added link to video about vac-forming acrylic) |

(→Health and Safety: removed red wording) |

||

| Line 61: | Line 61: | ||

Risk assessment: [[Equipment/VacuumFormer/RiskAssessment]] | Risk assessment: [[Equipment/VacuumFormer/RiskAssessment]] | ||

| − | The Vacuum Former is a potentially dangerous piece of equipment which must only be operated by members who | + | The Vacuum Former is a potentially dangerous piece of equipment which must only be operated by members who understand what they are doing and who take due care. The top things to always remember when using the Vacuum Former are: |

| − | * '''ONLY USE THE VACUUM FORMER IF YOU | + | * '''ONLY USE THE VACUUM FORMER IF YOU FEEL CONFIDENT AND COMPETENT TO DO SO''' |

* '''NEVER LEAVE THE VACUUM FORMER RUNNING UNATTENDED''' | * '''NEVER LEAVE THE VACUUM FORMER RUNNING UNATTENDED''' | ||

Revision as of 14:55, 24 February 2015

Class Orange equipment: Only use if you are confident doing so. Training is available if not.

(More about equipment classes)

WORK IN PROGRESS

The vacuum former has been installed in the space and can be used safely with the instructions provided here. However, this page is still considered a work-in-progress - please add useful tips about using the vacuum former here.

Summary

Vacuum forming is a technique that is used to shape a variety of plastics. It is used to form/shape thin plastic, usually plastics such as; polythene and perspex. Vacuum forming is used when an unusual shape like a ‘dish’ or a box-like shape is needed.

http://www.youtube.com/watch?v=scqkjU10198

The manual references an additional document that provides a more detailed guide including suggested timings and settings based on material. I have uploaded it to the wiki here: Vacuum Guide

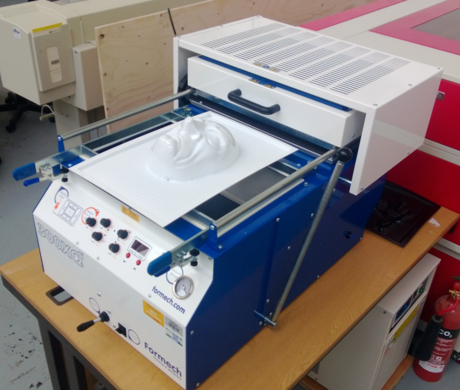

Formech 300XQ

Technical Specifications

- Material size 450x300mm / 18x12"

- Forming area 430x280mm / 17x11"

- Max. depth of draw 160mm / 6.3"

- Max. material thickness 6mm / .25"

- Overall width 650mm / 25"

- Overall height 530mm / 20"

- Overall depth 970mm / 38"

- Weight 75kg / 165lbs

Here are some examples we've made on the Vacuum Former(please add a photo of yours any time you do a job!)

Using the Vacuum Former

Owners

The Owners are those who have volunteered to be in charge of the equipment, organising maintenance, training others to use it, and generally being a point of contact. The current Owners of the Vacuum Former are:

- Stephen Woolhead

- New owners welcomed, get in touch!

If you have any questions, problems or concerns around the Vacuum Former, please use the mailing list thread:

Training

No formal training is required to operate the Vacuum Former. If you intend to make something using the vacuum former please read the Health & Safety and Safety Notes sections below before doing so. The manual is also available online in case you require additional information.

Informal training sessions will be listed in the Meetup diary

Requests for more sessions, or discussion about them should be directed to the discussion thread: Training:Vinyl Cutter

Health and Safety

Risk assessment: Equipment/VacuumFormer/RiskAssessment

The Vacuum Former is a potentially dangerous piece of equipment which must only be operated by members who understand what they are doing and who take due care. The top things to always remember when using the Vacuum Former are:

- ONLY USE THE VACUUM FORMER IF YOU FEEL CONFIDENT AND COMPETENT TO DO SO

- NEVER LEAVE THE VACUUM FORMER RUNNING UNATTENDED

As a trained user, you should be very aware of the following risks and how to deal with them:

FIRE - Heating the material for too long or with the wrong settings could result in the material igniting.

ELECTRIC SHOCKS - Regular maintenance & electric survey should mean machine is safe to use. Do not use if there are any signs of damage

BURNS - Caution should be taken when using machine, ensure formed part is cool before removing. Never operate with missing or damaged safety features.

Instructions

1. First, a former is made from a material such as a soft wood. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily.

2. The former is placed in a vacuum former at the lowest position.

3. A sheet of plastic (for example, compressed polystyrene) is clamped in position above the mould.

4. The heater is then turned on and the plastic slowly becomes soft and pliable as it heats up. The plastic can be seen to 'warp' and 'distort' as the surface expands.

5. After a few minutes the plastic is ready for ‘forming’ as it becomes very flexible.

6. The heater is turned off and the mould is moved upwards by lifting the lever until it locks in position.

7. The 'vacuum' is turned on and this pumps out all the air beneath the plastic sheet. Atmospheric pressure above the plastic sheet pushes it down on the mould. At this stage the shape of the mould can be clearly seen through the plastic sheet. When the plastic has cooled sufficiently the vacuum pump is switched off.

8. The plastic sheet is removed from the vacuum former. The sheet has the shape of the former pressed into its surface.

9. The excess plastic is trimmed so that only the plastic required remains - the completed item.

Reducing Windows

Reducing windows allow the use of smaller sheet material for smaller mouldings. Reducing windows allow for better sheet utilisation.

To fit the reducing window.

- Lift the clamp frame.

- Place the lower reducing window plate on to the top frame aperture so that the corner locating screws are aligned.

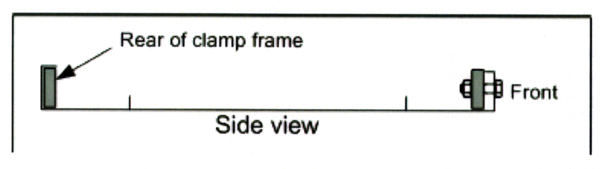

- Place the top reducing window plate on the underside of the clamp frame. There are folded sections on the front and rear. The rear edge has the larger return and wraps completely around the clamp frame bar. The front fold is smaller and returns against the front clamp frame bar. The fixing bolt is fitted through the clamp frame bar and reducing plate and secured using the fixing nut.. See diagram below of side view of the top plate fitting.

- Close the clamp frame. Check alignment oftop and bottom plate. Fit the required plastic material on the sealed lower reducing plate. The material toggle clamps will need adjusting so that the clamp frame can be locked to achieve the necessary clamping pressure.

Heating times

Different materials and thickness require different heating times, here is a list that has been found to produce good results

?????

Tips & Tricks

If the platform does not raise, ensure the heater is fully back.

DO NOT use to cook pizza

How long does it take to heat the plastic sheet?

- This depends on which material and thickness is specified.

How do I know when the plastic is ready to form?

- Generally speaking it is necessary with any new material to establish the correct heating cycle. Plastic is ready to form when it becomes soft and pliable especially nearer to the clamping frame. This is known as glass transition temperature (Tg). Once you have established the time you can set the heater timer for accurate and repeated heating cycles.

Why is the plastic webbing on the mould?

- Material is too hot.

- Insufficient vacuum.

- Excess of material. Use reducing windows.

- Poor mould design.

Why can't I achieve good definition on the finished part?

- Material too cold

- Mould too cold.

- Insufficient vacuum.

- Insufficient vacuum holes in the mould

Why Is the plastic thinning over the mould when formed?

- Sheet cooled whilst forming.

- Mould design with insufficient draft angles.

- Too thin plastic gauge.

- Pre-stretch required.

- Plug assist required.

Why does the plastic bubble and pit when heated?

- Material is Hygroscopic which needs to be pre-dried prior to forming.

- Overheating.

- Mould or plastic sheet too dusty

Why does the plastic stick to the mould when I try to release?

- Mould not fixed on baseboard.

- Insufficient draft.

- Mould undercuts.

Material Stock

If you have any requests for material stock, please add them the Log.

Stock material will be provided and an honesty box will be provided.

Maintenance

The maintenance of the Vacuum Former is carried out by the Owners, with some basic maintenance being carried out by Users on every job.

Maintenance Schedule

Every job: None required

As required, by users: Ensure the inside of the machine and the heater tray is cleared of dust, dirt and debris. Do not allow dirt and loose particles to build up, particularly on the heater tray.

Monthly: Check strength of vacuum and condition of seals. Check state of electrical system.

Maintenance Log

Installed on 26th July 2013. (with any luck)

Maintenance Shopping List

- Service Kit (~£50)

Further Information

Vac-forming acrylic: https://www.youtube.com/watch?v=LIHTECH5ObM

Installation

Installed on 9th May 2013.

Purchase

Full Purchase, Delivery and Installation (£2500)