Difference between revisions of "Equipment/Warco lathe"

RobCopcutt (Talk | contribs) (→Maintenance) |

RobCopcutt (Talk | contribs) |

||

| Line 35: | Line 35: | ||

= Owners = | = Owners = | ||

| − | The owners are experienced users who have volunteered to ensure members know how to safely operate the lathe before they become approved users. Their next responsibility is to ensure the lathe is in a safe usable condition. Time permitting, they will advise users on how to make best use of the lathe. | + | The owners are experienced users who have volunteered to ensure members know how to safely operate the lathe before they become approved users. Their next responsibility is to ensure the lathe is in a safe usable condition. Time permitting, they will advise users on how to make best use of the lathe. |

| + | |||

| + | So far the owners are; | ||

| + | * Roger Smith | ||

| + | * [[user:RobCopcutt|Robert Copcutt]] | ||

| + | * Jonny Waite | ||

| + | * Diana Probst | ||

| + | * Alaric Worrod | ||

| + | |||

| + | |||

= Training = | = Training = | ||

| Line 206: | Line 215: | ||

The risk assessment is at [[Equipment/lathe/RA]]. | The risk assessment is at [[Equipment/lathe/RA]]. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

= Training = | = Training = | ||

Revision as of 20:56, 21 June 2018

Class Red equipment: Do not use without specific training.

(More about equipment classes)

Contents

Summary

Makespace has a Warco lathe type GH-1330. It is a quality machine with a lot of power so it is capable of causing severe injury so it must only be used by those trained to operate it safely. The 'owners' are responsible for training new users and ensuring that it is maintained in a safe condition.

Using the lathe

The Myford is a metal turning lathe capable of machining circular cuts in material up to about 18cm (7 inches) in diameter and about 45cm (18") long. We also have vertical slides so milling operations can be performed on material up to about 10cm (4") cubed. The lathe is solidly built so with care micrometer level precision can be obtained. We now have a good selection of cutting tools and work handling apparatus so a wide range of different cutting operations can be performed on a wide range of materials. Some examples of what we have made:

Some of our accessories are listed at

[Accessories]

Health and Safety

The workpiece is spun at high speed with great force. Clothing or hair caught in the workpiece will not slow the motor! Before starting take time to check there is nothing likely to be caught in the machine.

Sharp edged chips can be thrown off the workpiece at high speed so eye protection is important.

The chuck key left in the chuck when the motor is started could become a missile. Before starting the motor make sure the chuck, and anything mounted in it, will not hit anything.

Metal turnings have very sharp edges. Avoid touching them whenever possible and use the brush provided to clean up the swarf.

To achieve real safety operator attitude is key. Trying to achieve unrealistic goals in limited time is the prime cause of accidents. Please take the time to plan your work and gain sufficient knowledge to perform it safely.

The risk assessment is at Equipment/lathe/RA.

Owners

The owners are experienced users who have volunteered to ensure members know how to safely operate the lathe before they become approved users. Their next responsibility is to ensure the lathe is in a safe usable condition. Time permitting, they will advise users on how to make best use of the lathe.

So far the owners are;

- Roger Smith

- Robert Copcutt

- Jonny Waite

- Diana Probst

- Alaric Worrod

Training

THE LATHE CAN CAUSE SERIOUS INJURY. ONLY APPROVED OPERATORS ARE PERMITTED TO USE IT.

To get the required training to become an approved operator please contact one of the owners.

The owners will help users make the best use of the lathe but it must be emphasised that learning to take full advantage of all the capabilities of it takes months of practice. The owners have limited time so members will need to take responsibility for much of their own training. More details about the training can be found at

Instructions

We a copy of a workshop safety manual from the CRC that provides a comprehensive guide to using lathes and related equipment. If you want to use the lathe, or simple know what it can do, please have a look at it - in Makespace.

Maintenance

The lathe bed should be frequently brushed clean and re-oiled to minimize wear on the precision slides.

There are a number of oiling points that need periodic application of oil with the supplied pot.

The drive belts need replacing if they get worn or damaged.

Members must be fully trained before using the lathe so please contact the owners if you would like training.

Training Notes for the Warco GH1330 Lathe Part 1 Safety. A lathe is potentially one of the most dangerous machines in a workshop, however if correctly used it is extremely safe. It is you that makes the difference.

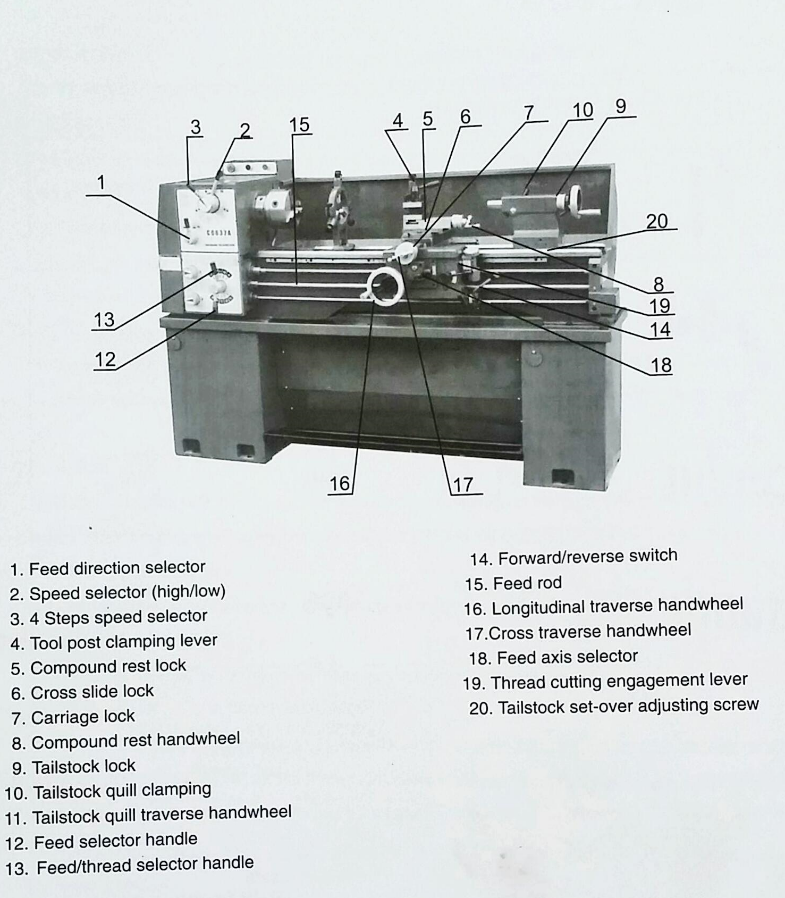

Always make sure of two things when using a lathe: 1. That the work area is safe, there is nothing lying on the lathe that shouldn’t be, especially the chuck key, more on that later. Ensure that your work is held firmly in the chuck, also check before starting the lathe that the feed drives are not engaged that the chuck will not collide with any tools. 2. You have nothing on you that can get caught in the mechanism of the lathe, beware of lose clothing, long sleeves, jewellery and especially long hair. All of these are a total No-no. Whilst eye protection is mandatory do not wear anything that will impair your hearing – if you listen to the lathe while it cuts the lathe will tell you how well you are doing. Getting to know your lathe Parts of your lathe – your trainer will demonstrate the function of each part

Setting up your lathe

Switch on the wall and the e-stop released, the power light comes on. If you power up with the forward/back lever in the run position you have to go to neutral first then re-select.

Checking the lathe. Do a visual check to see that your work area is free from items that could fall into the lathe or become entangled in the lathe. Lubrication/oil checks. There are three oil windows which should have oil halfway up the glass. If they do not this is a major panic but report it to management. There are sight glasses for spindle gearbox, lower gear box (lead screw), and carriage.

Select Speed. Spindle MUST be stationary. They are crash gears with no concept of synchromesh, so the spindle has to be stopped entirely. Nudge chuck by hand until meshing happens. The guard must be closed to start system.

Preparing the job The 3 Jaw Chuck The main chuck is 3-jaw chuck. We also have a 4-jaw chuck, which is used for irregular shaped items. Always leave the 3-jaw chuck on the lathe when done, some people cannot mount and de-mount the 4-jaw safely as it is very heavy.

Phase 2 of the training covers changing chucks.

One of the most dangerous things that you can do on a lathe is to leave the chuck key in the chuck Now place your job in the lathe. Cutting tools should all be set for centre height

Place the bar centrally into chuck, tighten up nicely. The first job is usually facing off, getting the manky end square. Get a good end to start from. Tools should all be set for centre height. Drop-in and tighten should give you the correct height, but it's best to check. Big spanner to loosen quick-change tool to rotate it. You can re-align it by coming up to chuck, which is the best square. Loosen off, bring up to chuck, and tighten. The spring washer stops the nut vibrating. A little beyond humans doing finger tight.

Centering is absolutely vital with parting-off tools. Make sure all is tight there. Usually only displace/swing for taper turning. Don't use it for fine feeds - the DRO does not follow it. Starting your lathe The guard must be closed to start system. Starting on right-hand handle. Rock to right and down for forwards. Knock it up to coast to a stop. Faster stop is foot pedal.

Emergency Stop Foot Pedal Slight touch switches the motor off and further push engages brake drum and stops it dead. The emergency brake should not be used for normal stops as it wears the brake.

Cutting tools May be right and left-hand. If cutting back into a shoulder you'll want a left-hand. Feed in gently so it doesn't dig. The faces of the quick-change tool are at right angles, so you can bore. • High speed steel tools give a finer finish but generally require more maintenance – left of picture • Carbide tipped tools cannot have the cutting edges changed – centre of picture • Carbide insert tools are designed for toughness, and not surface finish – right of picture

Quick Change Tool The big spanner is used to loosen the quick-change tool and rotate it. You can re-align it by bringing it up to the chuck and checking it is square to it and tighten it again. • The tool holders are drop-in and tighten type and normally give you the correct height, but it's best to check • Being square is absolutely vital with parting-off tools. Again, make sure all is tight here. • Usually, you would only displace/swing the head for taper turning, see training part 2. • Don't use it for fine feeds - the Digital Read Out does not follow it. The DRO is covered in part 2 Cutting Notes • Square inserts are for heavy rough cuts and don't go right up to a shoulder. • Chamfer bits exist, and so do thread cutting bits, as do internal/external cutting bits. More on part 2 of the course. • Chamfer bits are better when re-angling end of your work • The tools that are along the back of the lathe should be kept there • Replacing tools means you will have to adjust the height nut on each cutting tool. Lock and then re-test. Spring washer stops the nut vibrating. Tighten a little beyond humans doing finger tight. • All tools have a tiny radius at the end, so if you are cutting up to a shoulder you can either undercut a little and sink the radius in, or you can undercut the shank. A lot of times it doesn't matter, until you need to fit a bearing. • Plan to cut slightly larger than your final cut and measure prior to cutting the last cut and do a very fine cut.

Dead Stop Is used to prevent you driving the cutting tool and its mounting into the rotating chuck, which is another big No-No in lathe working and it will send you back to retraining, if the lathe is still working that is. Adjustable with dial. It is used whilst hand-feeding only.

Lubrication You may use the built-in pump system which can be messy or the hand pump oil can that lives with the lathe. Cross cut (end or face cutting)

Face Cutting is done by cutting across the end of the metal and using the cross feed which is calibrated in DIAMETER. 5 mm is a .25mm infeed. Your instructor will demonstrate a cut to you then you can do one, try both a manual cut and then a power feed one. Long cut (turning) Turning is done by cutting down the rounded side of the metal and using the longitudinal wheel. Your instructor will demonstrate a cut to you then you can do one, try both a manual cut and then a power feed one. Always plan to get your penultimate cut an extremely small amount short of your final cut, this way your final cut will be extremely fine and be smoother. Carbide inserts are designed for toughness, and not surface finish. All tools have a tiny radius at the end, so if you are cutting up to a shoulder you can either undercut a little and sink the radius in, or you can undercut the shank. A lot of times it doesn't matter........until you need to fit a bearing.

Always be careful that you do not drive the cutting tool into the moving chuck, particularly when using the power feed. Tail Stock Centring tool • Lock off slide and advance with longer handle at the rear. • Tools vary, so leave plenty of room.

The lever-action drill head is for smaller drill bits, and gives you some feel of how the cut is going. Power feed. • Take the tool well clear of the work and make sure the lathe is working correctly before you start to cut • Check you have set the correct direction • It’s always better to run slower and a better surface usually results. • Cross feed or transverse-feed drive is selectable, but only one at a time.

Evaluation Demonstrate that you understand the following: • All matters safety related • How to start up the lathe • How to chose the correct speed for the job and how to select the speed on the gearbox • Mount a job in the 3-jaw chuck and use of the safety cover • How to set up the quick release tool spindle with the tool and set the correct angle • Demonstrate an understanding of the different types of cutting tolls and when you would use them • Demonstrate how to set up the poser feed and run it • Explain what boring is and the difficulties it presents • Set up the dead stop and the emergence stop foot pedal and show how they work • Explain the difference between the calibration on the apron and the cross slide • Show how to use the tailstock and centering tool to drill a hole into the end of a job Shutdown at end of work. Hit e-stop and then turn off at wall. Cleaning: leave it clean! Take work out, replace all the bits you may have changed/removed, brush stuff off the swarf from slides and other surfaces with the paintbrush and swarf. Brush it down to the collecting tray below, which can then be pulled out and emptied. For clearing up gloves are mandatory. Swarf is razor sharp and can go septic if it gets under your skin. Gloves are kept in the blue bin just outside the secure workshop door

Alaric Worrod 2018-05-31

Health and Safety

The workpiece is spun at high speed with great force. Clothing or hair caught in the workpiece will not slow the motor! Before starting take time to check there is nothing likely to be caught in the machine.

Sharp edged chips can be thrown off the workpiece at high speed so eye protection is important.

The chuck key left in the chuck when the motor is started could become a missile. Before starting the motor make sure the chuck, and anything mounted in it, will not hit anything.

Metal turnings have very sharp edges. Avoid touching them whenever possible and use the brush provided to clean up the swarf.

To achieve real safety operator attitude is key. Trying to achieve unrealistic goals in limited time is the prime cause of accidents. Please take the time to plan your work and gain sufficient knowledge to perform it safely.

The risk assessment is at Equipment/lathe/RA.

Training

THE LATHE CAN CAUSE SERIOUS INJURY. ONLY APPROVED OPERATORS ARE PERMITTED TO USE IT.

To get the required training to become an approved operator please contact one of the owners.

The owners will help users make the best use of the lathe but it must be emphasised that learning to take full advantage of all the capabilities of it takes months of practice. The owners have limited time so members will need to take responsibility for much of their own training. More details about the training can be found at

Instructions

Maintenance

The lathe bed should be frequently brushed clean and re-oiled to minimize wear on the precision slides.

Three of the bearings have oil pots that need topping up occasionally.

The two drive belts need replacing if they get worn or damaged.

Peripheral tools and accessories

Running the lathe will require many accessories, there is a suggested list here:

Tools Available

There are a number of 250-201 tool holders which fit on the quick change tool post.

| Tool | Description | Steel Insert | Aluminium/Plastic Insert |

|---|---|---|---|

| SSSCR1/2"-3 | Neutral 45° end and side cutting edge angle for positive 45° SCMT inserts. | SCMT 09T3 | SCGT 09T3 |

| SSBCR1/2"-3 | SCMT 09T3 | SCGT 09T3 | |

| SWGCR1/2"-3 | Right hand 90 degree end or side cutting edge angle for 80 degree WCGX insert | WCGX | WCRX |

| SWUCR3/8"J3 | WNMG 060404 | ||

| SER1/2"-11 | External threading tool | ||

| S1/2J-SIR11 | Internal threading tool | ||

| MGEHR1/2"-02 | Cut off tool | MGMN | MGGN |

| S-SSKCR3/8"J3 | SCMT 09T3 | SCGT 09T3 | |

| S-SSSCR3/8"J3 | SCMT 09T3 | SCGT 09T3 | |

| SCLCR1212F09 | Right? | CCMT 09T3 | CCGT 09T3 |

| SCLCL1212F09 | Left? | CCMT 09T3 | CCGT 09T3 |

| SRDCN 1616h 08 | Radius lathe tool (property of Robert K.) | RCMT 0803 | RCGT 0803 |

| n/a | Knurling tool | n/a | n/a |

| n/a | HSS Cut off tool | n/a | n/a |

More info: https://www.cutwel.co.uk/learn-the-turning-tool-iso-code-system

Some recommended videos

Joe Pieczynski is extremely knowledgeable and has made many videos. Here is one about the optimum chip for high speed cutting. https://www.youtube.com/watch?v=12YShfHSaYs

Reversed cut-off tool trick.

https://www.youtube.com/watch?v=-RZRq0olsxM