Printing with TPU

Contents

TPU 95A – About the material

TPU stands for Thermoplastic Polyurethane. According to Wikipedia, TPU has many applications including automotive instrument panels, caster wheels, power tools, sporting goods, medical devices, drive belts, footwear, inflatable rafts, and a variety of extruded film, sheet and profile applications. TPU is also a popular material found in outer cases of mobile electronic devices, such as mobile phones. It is also used to make keyboard protectors for laptops.

95A – is the shore harness. The higher the number the harder the material. The letter relates to the test used to measure the hardness. You can only compare numbers with the same letter, generally the higher the letter the harder the material. I couldn’t get exact number for the filaments we stock but representative shore hardnesses for ABS and PLA are 100D and PLA 80D respectively.

TPU 95A is a semi-flexible and chemical resistant filament with strong layer bonding and high abrasion resistance.

Other hardnesses of TPU are available, for example:

- Ninjatek Ninjaflex 85A

- Ninjatek semiflex 98A

Because our printers are fed via a boden tube we can’t use anything softer than 95A, so 98A (semi-flex) is fine but ninjaflex is not. In in doubt go off the shore hardness and even then I’d recommend ordering a sample before committing to a whole spool.

Printing properties of TPU 95A

- It is soft

- Slow to respond, will not extrude straight away and will keep extruding after feeding stops

- More likely to jam in the feeder

- Melts at same temperature as PLA

- More hydrophilic than PLA/ABS

- More Expensive than PLA/ABS - 10p per gram, separate button on iZettle

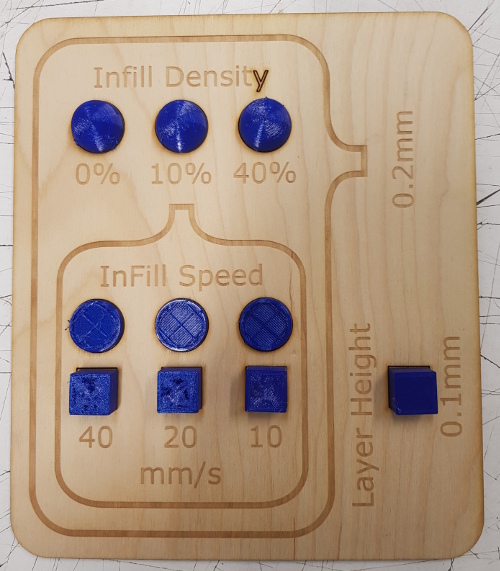

- Hardness/flexibility of result highly dependent on design and how it is printed (see board)

Loading/unloading considerations

- Be careful loading it into the feeder, it is more likely to “get lost” – make sure it comes out of the top.

- It might take slightly longer to feed through

- It might not unload in one go. Either use the release lever or hit cancel and unload again.

Printing consideration

- TPU is more likely to jam for no reason than PLA or ABS

- Print slowly, makes up for the slow response of the material to the feeder

- In particular the infill speed on the generic TPU 95A Cura profile seems to fast (see board)

- Either have more retraction than normal or no retraction, this is due again to the slow feed response. I prefer no retraction as it reduces the change of the filament jamming in the feeder.

- Brim – the material sticks well at a lower bed temp to PLA but a brim can help stabilise tall thin prints.

- Raft – seems to work fine, removing the raft was easy but the surface finish on the bottom of the print is even worse than you'd normally expect with a raft.

- Support – needs to be printed more slowly than the default in cura. Reducing the support speed to 10 mm/s seems to do the trick. Dependning on the geometry of what you're printing support may be less effective than you'd expect as the print may "flex" away from the support during printing.

- Removing prints. The material sticks well at low temperatures but also comes off cleanly with the application of a little force. The octopus required me to pull each leg off one by one before I could remove the whole.

Profiles

Printers

Both our PLA printers have a TPU profile available, this has the same nozzle temperature as PLA but a lower bed temperture.

Makespce Cura PC

The PC in the space has been updated to support TPU.

- Select TPU 95A as the material

- Select one of the custom TPU profiles (do not use the 'Normal Quality' profile)

Your own computer running Cura

This archive contains modified cura profiles to use in cura 3.6.0 (and possibly other versions too). Use the "manage profiles" dialog to import them. To use the profiles, you should first select "Generic->TPU 95A" as the material then select one of the profiles.