Equipment/3D Printer/Up

Class Red equipment: Do not use without specific training.

(More about equipment classes)

Contents

The Up! 3D Printer

YOU CAN ONLY USE THE UP 3D PRINTER IF YOU HAVE BEEN TRAINED ON IT

Being trained on the Makerbot is a different induction from being trained on the Up!

The UP! 3D printer suffered an electronics failure, and has had its control circuitry replaced with a RepRap Melzi controller board. Software required to control the Up! is installed on the 3D printer PC, alongside the Makerbot.

Owners/Trainers: Brian Starkey

Caveats

The Up! is intended for use by those who wish to take more control of the 3D printing process and are interested in experimentation. The software workflow is less-friendly than the Makerbot, but infinitely more flexible.

General Health and Safety

The 3D printers are excellent tools for either making small parts, or rapid prototyping. At the same time it is an expensive tool with a (small) risk of injury and fire, so is very important you know how to use it to avoid damaging yourself and the machine. The 3D printer is a potentially dangerous piece of equipment which must only be operated by members who have received appropriate training and who take due care. The top things to always remember when using the 3D printers are:

- ONLY USE THE 3D PRINTER IF YOU HAVE BEEN TRAINED

- ONLY USE THE 3D PRINTER IF YOU HAVE READ THE INSTRUCTIONS

- NEVER LEAVE THE PRINTER RUNNING UNATTENDED

As a responsible user, you should be very aware of the following risks and how to deal with them:

HEAD CRASH - incorrect calibration could cause the nozzle to hit the platen at job start

- Calibration must be carefully checked on each startup

TRAPPING - The head and bed of the machine are moved by programs in the machine's memory.

- Be careful when near the machine, it will possibly move even if the PC is off

- Ensure you are familiar with the 'pause' and 'stop printing' functions on the Makerbot so that in an emergency you can quickly halt printing.

BURN RISK - the platen on the printers are heated, and will reach temperatures up to 253 degrees during a print run which could cause skin burns. The extrusion nozzles also get very hot. Do not touch either of these areas while printing, and keep the Makerbot's guard door securely closed while printing.

- Be careful when the machines have recently been used, as they may still be hot enough to burn.

ELECTROCUTION - as with all mains powered devices there is a small risk of danger from exposed wires. Always do a manual check that the wiring is safe, no cores are exposed or wires trapped.

FUMES - In high concentrations ABS fumes may cause irritation. Do not spend hours bent over the printer whilst it is printed, and turn on the extractor/inlet fans of the main space when doing long print runs.

Operating Instructions

Power-on

The Up! requires two power supplies - a 20V high power supply which drives the bulk of the printer (motors, heaters) and a separate 5V supply which drives the filament feeder.

Both supplies are plugged in to a switchable power strip plugged in to the wall behind the PC - it is marked "Up". Turning this strip on will power up the printer.

Power-down

Before powering off, remember to unload the filament and return it to the box.

Before turning the power off, home all the axes using the White home button or the G-code G28, then turn off the main switch.

Control Software (Pronterface)

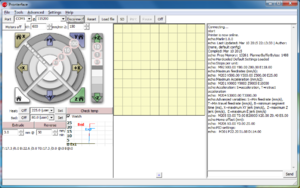

The default control software for the Up! is Printrun, a.k.a. Pronterface, a Python-based Reprap host software.

Printrun 2014.03.10 is installed on the 3D printer PC under Users/makespace-user2/My Documents/Up/Pronterface. There is a shortcut on the Desktop.

Pronterface is only a control software, it interfaces with the printer, however it depends on external software (a Slicer) to turn 3D models into commands that the printer can understand.

Printer startup

After powering on the printer, open Pronterface.

Select the COM port and baud rate in the top-left hand corner. The COM port is normally COM5 and the baud rate is 115200, then click Connect.

After several seconds the command pane on the right of the window should state that the printer is connected and print some details about the machine.

Controlling the printer

G28)Movement

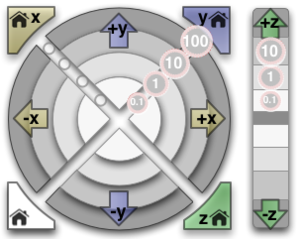

The circular arrangement of buttons can be used to directly control the printer axes. The axis orientation is shown on the picture to the left. e.g. Movement in +Z direction moves the bed further from the extruder

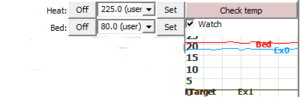

Heaters

The bed and extruder heaters can be manually controlled from the controls immediately below the movement buttons. The temperatures can be monitored by checking the Watch checkbox on the right, which will update the plot in real-time. Clicking the plot will open a new window displaying the temperature plot.

G-code

G-code can be entered in the box in the bottom-right of the window. These will be sent to the printer immediately on pressing "Enter" or clicking the Send button.

The full list of G-code understood by the printer can be found on the RepRap website, supplemented by a few non-standard extensions implemented by the Marlin firmware.

Printing

Loading filament

To load/unload filament, you will need a hot extruder. Use the heater controls to heat up the extruder to the appropriate temperature for the plastic you are loading/unloading.

Once the extruder has warmed up, feed the end of the filament into the underside of the filament feeder and press the microswitch. Press the microswitch a couple more times until sufficient filament is available to feed into the extruder.

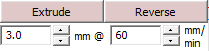

In Pronterface, set the extrusion settings to 5mm @ 60mm/min, and feed the filament into the top of the extruder. While gently pushing the filament downwards, click the Extrude button one-or-more times until you can feel the filament being pulled by the extruder. Once the extruder has a hold on the filament, continue to use the Extrude button to feed more plastic, until you get a clean, uniform thread out of the hot-end.

It is often necessary to clear away a blob of plastic from the hot-end during this process.

Filament feeder

The Up! has a small motor which pre-feeds filament from the reel so that the extruder doesn't have to work so hard. The feeder requires power (see [[#Power-on|]]), and will feed for several seconds every time the microswitch is depressed. During printing, the extruder should be able to activate the microswitch itself as it pulls the filament tighter, however it is advisable to keep an eye on it and be ready to press the switch yourself if you think it necessary.

The main risk is that a taught filament causes skipped steps in the X-axis during a rapid move.

Unloading filament

Unloading filament is the opposite of loading. Use the Reverse button in the extruder controls to feed the filament out of the extruder, while gently pulling the filament upwards. You will likely need to click Reverse several times, unless you have set a particularly long extrude length.

The filament feeder is (currently) strictly one-way. Do not attempt to pull the filament back through the feeder!. Use a pair of side-cutters to cut the filament as close to the underside of the feeder as possible, and press the switch to feed it out.

Printing a file

Once you have a G-code file of your sliced model, you can print it from Pronterface.

- Click the Load File button and select your

.gcodefile - Your part should now show up in the middle pane of Pronterface

- Check the output in the command pane on the right looks sensible (i.e. no insane dimensions)

- Click the middle pane to open the G-code viewer, and use the slider on the right to check the slicer output

- The G-code viewer shows movement lines as well as extrusion lines, the movement lines are shown in a different colour

- When you are satisfied, click print in the main Pronterface window!

Pronterface will give an estimated print time when you load the file. In the status bar at the bottom of the window it will continually re-estimate the time remaining throughout the job

Cost

Currently we charge 10 pence per gram for prints, this is to cover the cost of material plus a little for wear and tear and other consumables. You can weigh printed parts using the scales next to the blue honesty box. Please put your money into the blue labelled honesty box on the shelf above the printer.

Bed Levelling/Calibration

The Up! seems to be less sensitive to slight misalignments in the bed than the Makerbot. In part this is probably due to the high-adhesion ABS build plate.

If you do feel the need to level the build plate, then there are 3 allen-key bolts on the underside of the pinkish bed mounting block. The bed rides on 3 silicone grommets, and by adjusting the bolts you can compress the grommets to varying degrees to achieve a level build plate.

At present the bed levelling procedure is a fairly manual affair, requiring entry of G-code into the Pronterface command window. The suggested calibration procedure is given below.

- Load your G-code file into Pronterface.

- Take note of the part dimensions reported in the command window.

- Enter the G-code commands below

- In the G-codes below, the following substitutions should be used:

- <centre_x>, <centre_y>: The build centre coordinates as specified when Slicing

- <min_x>, <min_y>, <max_x>, <max_y>: The minimum x,y coords as shown by pronterface. e.g.: from <min_x> mm to <max_x> mm in X

G28 # Home all axes # Note: Use Z2 initially to make sure there is enough clearance on the extruder G0 X<centre_x> Y<centre_y> Z2 # If you are happy that there is 2 mm more space in the Z-axis, continue with the calibration with <z_min> = 0 # Otherwise try larger values of <z_min> (decimals are allowed) e.g. <z_min> = 0.2. Units are in mm # In this case you should re-slice your part, specifying <z_min> in the Z offset field on the Printer Settings tab # Repeat the following commands, adjusting the bolts to provide a < 1 mm gap between the extruder and the bed in all positions G0 X<centre_x> Y<centre_y> Z<min_z> G0 X<min_x> Y<min_y> Z<min_z> G0 X<max_x> Y<max_y> Z<min_z> G0 X<min_x> Y<max_y> Z<min_z> G0 X<max_x> Y<min_y> Z<min_z> G28 # Home all axes

Slicing

Firmware

The firmware is Marlin, with configuration changes for the hardware. You can find the branch on github: https://github.com/usedbytes/Marlin/tree/makespace-up

I wasn't planning on trying to push this upstream because I don't think it has wide appeal.

Maintenance

The maintenance of the 3D printer is carried out by the Owners, with some basic maintenance being carried out by Users on every job.

Maintenance Schedule

Continuous Maintenance (Every job, done by all 3D Printer Users)

- Clean the platen of any plastic remnants

- Check the new material is feeding OK and the reel has enough on it

Basic Maintenance (Every week, done by 3D Printer Maintainers)

- Check the security and condition of all cabling

- Check the platen coating and re-paint any areas if necessary (green paint is in a pot with the printer)

Full Maintenance (Every 4 weeks, done by 3D Printer Maintainers)

- Tasks as per Basic Maintenance, plus

- Strip coating off platen and re-paint with a fresh coat

- Calibration check, if issues have been reported

Maintenance Notes

Our printer has been modified to support solid 3mm ABS plastic sheets as the base. These are disposable; they have to be cut from the big sheet and drilled using the jig we have created. The bolted-down solid plastic dramatically reduces problems with warping, and it also saves time and material when printing: you should disable the automatic raft.