Difference between revisions of "Equipment/AxminsterScrollSaw"

Perfectphase (Talk | contribs) m (→Blade Selection) |

Perfectphase (Talk | contribs) m (→Maintenance) |

||

| Line 134: | Line 134: | ||

Every month inspect for damage and general wear and tear and asses state of stock blades and replace as needed. | Every month inspect for damage and general wear and tear and asses state of stock blades and replace as needed. | ||

| − | + | Replacement blades [http://www.axminster.co.uk/pegas-scroll-saw-blade-mixed-pack-prod878221/ Scroll Saw Blade Mixed Pack (60 blades)] £15 | |

| − | + | ||

| − | Replacement blades [http://www. | + | |

== Further Information == | == Further Information == | ||

Revision as of 02:44, 8 April 2013

Equipment / Scroll Saw

Contents

Summary

A scroll saw is a small electric or pedal-operated saw that is useful for cutting intricate curves in cases where a jigsaw or coping saw is not appropriate. It is capable of creating curves with edges. It is somewhat similar to a band saw, but unlike band saws, in which the saw blade is a continuous loop, scroll saws use saw blades similar to those of coping saws and operate through a quick reciprocating up and down motion.

A scroll saw has two main advantages when compared to a band saw. The first is that the blade can be removed and placed in situ through a pre-drilled starting hole. This feature allows interior cut-outs to be made without creating an entry slot for the blade through the edge of the workpiece. Second, a scroll saw can cut significantly more intricate curves.

Owners

Health and Safety

Sharp Object/material

- Power supply to be disconnected when changing Blades.

- Wait for the blade to stop moving before removing the material or attempting any adjustments.

Slips, Trips and Falls

- Waste material/offcuts to be kept clear of work area.

Fire

- Equipment will be checked for defects before each use to minimise the risk of possible electrical faults or fire.

- Carbon Dioxide extinguisher to be available for any electrical fires

Electric shock

- The equipment will be checked before each use to ensure that there are no defects in the casing, battery or cutting head.

Sight/Noise/Dust/Vibration

- P.P.E. to be worn when using the equipment.

- Regular brakes to be taken to prevent fingers becoming numb

Repetitive Action/Physical Fatigue

- Regular breaks to be taken if work is lasting more than 5 minutes in duration

Training

No mandatory training is required to use this tool.

Optional training will be available in the near future.

Instructions

The scroll saw is a very safe tool to use, if you've never used one, here is a quick introduction video

For detailed instructions se the manual or the saw Scroll Saw Manual

Because of the thin blade, using a scroll saw needs a delicate touch. If you push too hard, you will all too easily snap the blade. To cut a curved shape, feed the work with both hands, holding the wood flat against the saw's base while applying gentle forward pressure. The key is patience. Allow the work to feed through the saw blade slowly, without forcing it. If you begin to feel a greater level of resistance this will probably be due to a blunt blade.

A common mistake is to accidentally exert sideward pressure while feeding the wood through. If this begins to happen, relax the pressure on the wood by lessening the fingertip pressure. However, do not let go of the wood, just relax the pressure.

Blade Selection

Scroll saw blade sizes typically range from 1 to 12. Each blade size is designed to be used with different thicknesses of wood. The smaller the blade you can pick, the easier it is to cut delicate curves. The rough selection is as follows:

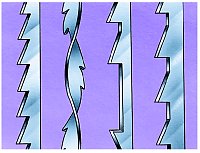

Scroll Blades (Shown on the left) are recommended for cutting thicker and harder material.

Spiral Blades (Shown 2nd from the left) blades are twisted so teeth point outward in every direction. A 360° capacity allows cutting in any direction without turning your work.

Reverse Blades (Shown 2nd from right) Teeth are pointed in both directions to give splinter free cutting on the top and bottom.

| Blade size | Hardwood thickness | Softwood Thickness |

|---|---|---|

| 1 to 2 | 1/4" | 1/4" |

| 3 to 4 | 1/2" | 3/4" |

| 5 to 6 | 1/4" to 3/4" | 1/4" to 1" |

| 7 to 9 | 1/4" to 1" | 1/4" to 2" |

| 10 to 12 | 3/4" to 2" | 3/4" to 2" |

Technical Specification

| Cuts per Minute | 400-1,400 |

| Max Depth of Cut | 65mm |

| Net Weight | 29kg |

| Overall L x W x H | 620 x 285 x 310mm |

| Power | 120W |

| Rating | Trade |

| Stroke | 10 & 20mm |

| Table Size | 460 x 235mm |

| Table Tilt | 0-45° |

| Throat | 460mm(18") |

Tips & Tricks

- Always test run the cut without power to ensure there are no problems and your hands are clear of the blade.

- Be aware of the location of any power cords when operating the saw, keeping them out of the path of the cut at all times.

- Be aware of where cut off pieces of lumber will fall, to avoid injuries; if possible clamp or support the offcuts.

- Be especially careful of the placement of your hands when cutting at an angle. if possible clamp the workpiece so you hands are well clear of the machine when cutting.

- A circular saw blade will almost always kick straight back. Watch your body position. Keep slightly to the side, and never keep a hand behind the blade.

Maintenance

Every month inspect for damage and general wear and tear and asses state of stock blades and replace as needed.

Replacement blades Scroll Saw Blade Mixed Pack (60 blades) £15