Difference between revisions of "Equipment/AxminsterScrollSaw"

Perfectphase (Talk | contribs) m (→Blade Selection) |

RobCopcutt (Talk | contribs) |

||

| (17 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| + | {{OrangeTool}} | ||

| + | |||

[[Equipment|Equipment]] / Scroll Saw | [[Equipment|Equipment]] / Scroll Saw | ||

| − | [[File:ScrollSaw.jpg|thumb|460px|right| | + | [[File:ScrollSaw.jpg|thumb|460px|right|Axminster Scroll Saw]] |

= Summary = | = Summary = | ||

| − | A scroll saw is a small electric | + | A scroll saw is a small electric saw that is useful for cutting intricate curves in cases where a jigsaw or coping saw is not appropriate. It is capable of creating curves with edges. It is somewhat similar to a band saw, but unlike band saws, in which the saw blade is a continuous loop, scroll saws use saw blades similar to those of coping saws and operate through a quick reciprocating up and down motion. |

A scroll saw has two main advantages when compared to a band saw. The first is that the blade can be removed and placed in situ through a pre-drilled starting hole. This feature allows interior cut-outs to be made without creating an entry slot for the blade through the edge of the workpiece. Second, a scroll saw can cut significantly more intricate curves. | A scroll saw has two main advantages when compared to a band saw. The first is that the blade can be removed and placed in situ through a pre-drilled starting hole. This feature allows interior cut-outs to be made without creating an entry slot for the blade through the edge of the workpiece. Second, a scroll saw can cut significantly more intricate curves. | ||

| Line 11: | Line 13: | ||

== Owners == | == Owners == | ||

| + | * Michael Dales | ||

== Health and Safety == | == Health and Safety == | ||

'''Sharp Object/material''' | '''Sharp Object/material''' | ||

* Power supply to be disconnected when changing Blades. | * Power supply to be disconnected when changing Blades. | ||

| − | * Wait for the blade to stop moving before | + | * Wait for the blade to stop moving before attempting any adjustments. |

'''Slips, Trips and Falls''' | '''Slips, Trips and Falls''' | ||

| Line 42: | Line 45: | ||

== Instructions == | == Instructions == | ||

| − | The scroll saw is a | + | The scroll saw is a relatively safe tool to use. if you've never used one, here is a quick introduction [http://www.youtube.com/watch?v=TU3V3MdkaJg video] |

For detailed instructions se the manual or the saw [http://makespace.org/wiki/index.php/File:AWFS18_manual.pdf Scroll Saw Manual] | For detailed instructions se the manual or the saw [http://makespace.org/wiki/index.php/File:AWFS18_manual.pdf Scroll Saw Manual] | ||

| Line 51: | Line 54: | ||

===Blade Selection=== | ===Blade Selection=== | ||

| − | Scroll saw blade sizes typically range from | + | |

| + | [[Image:ScrollSawBlades.jpg|right]] | ||

| + | |||

| + | Scroll saw blade sizes typically range from 1 to 12. Each blade size is designed to be used with different thicknesses of wood. The smaller the blade you can pick, the easier it is to cut delicate curves. The rough selection is as follows: | ||

| + | |||

| + | Scroll Blades (Shown on the left) are recommended for cutting thicker and harder material. | ||

| + | |||

| + | Spiral Blades (Shown 2nd from the left) blades are twisted so teeth point outward in every direction. A 360° capacity allows cutting in any direction without turning your work. | ||

| + | |||

| + | Reverse Blades (Shown 2nd from right) Teeth are pointed in both directions to give splinter free cutting on the top and bottom. | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 79: | Line 91: | ||

|3/4" to 2" | |3/4" to 2" | ||

|} | |} | ||

| + | |||

| + | [http://www.youtube.com/watch?v=AEMe8meAOSw Choosing the Right Blade for Your Scroll Saw (Video)] | ||

===Technical Specification=== | ===Technical Specification=== | ||

| Line 116: | Line 130: | ||

== Tips & Tricks == | == Tips & Tricks == | ||

| − | * | + | * You must guide the wood into the blade SLOWLY, because the teeth are very small, and cut ONLY on the down stroke. If you push the wood into the blade too rapidly, you can easily break the blade. |

| − | * | + | * The teeth on the blade will wear out sooner or later. The blade must therefore be replaced often to obtain the best cutting results. A blade will stay sharp for half an hour to 2 hours of continuous running, depending on the material being cut. |

| − | * Be aware | + | * Be aware that the blade has a tendency to follow the grain of the wood. You can compensate for this by watching the grain carefully and guiding the wood past the saw blade. |

| − | + | * There is a jig and guide on the near right hand side of the bed to help you mount a blade in the bits. See picture to show where. [[File:scrollclamp.jpg|right|frame|Blade mounting jig on scroll saw]] | |

| − | + | ||

== Maintenance == | == Maintenance == | ||

Every month inspect for damage and general wear and tear and asses state of stock blades and replace as needed. | Every month inspect for damage and general wear and tear and asses state of stock blades and replace as needed. | ||

| − | + | Replacement blades [http://www.axminster.co.uk/pegas-scroll-saw-blade-mixed-pack-prod878221/ Scroll Saw Blade Mixed Pack (60 blades)] £15 | |

| − | + | ||

| − | Replacement blades [http://www. | + | |

== Further Information == | == Further Information == | ||

| + | [http://www.youtube.com/watch?v=TU3V3MdkaJg Introduction to using a scroll saw (video)] | ||

| + | |||

| + | [http://makespace.org/wiki/index.php/File:AWFS18_manual.pdf Scroll Saw Manual] | ||

Latest revision as of 19:49, 21 June 2018

Class Orange equipment: Only use if you are confident doing so. Training is available if not.

(More about equipment classes)

Contents

Summary

A scroll saw is a small electric saw that is useful for cutting intricate curves in cases where a jigsaw or coping saw is not appropriate. It is capable of creating curves with edges. It is somewhat similar to a band saw, but unlike band saws, in which the saw blade is a continuous loop, scroll saws use saw blades similar to those of coping saws and operate through a quick reciprocating up and down motion.

A scroll saw has two main advantages when compared to a band saw. The first is that the blade can be removed and placed in situ through a pre-drilled starting hole. This feature allows interior cut-outs to be made without creating an entry slot for the blade through the edge of the workpiece. Second, a scroll saw can cut significantly more intricate curves.

Owners

- Michael Dales

Health and Safety

Sharp Object/material

- Power supply to be disconnected when changing Blades.

- Wait for the blade to stop moving before attempting any adjustments.

Slips, Trips and Falls

- Waste material/offcuts to be kept clear of work area.

Fire

- Equipment will be checked for defects before each use to minimise the risk of possible electrical faults or fire.

- Carbon Dioxide extinguisher to be available for any electrical fires

Electric shock

- The equipment will be checked before each use to ensure that there are no defects in the casing, battery or cutting head.

Sight/Noise/Dust/Vibration

- P.P.E. to be worn when using the equipment.

- Regular brakes to be taken to prevent fingers becoming numb

Repetitive Action/Physical Fatigue

- Regular breaks to be taken if work is lasting more than 5 minutes in duration

Training

No mandatory training is required to use this tool.

Optional training will be available in the near future.

Instructions

The scroll saw is a relatively safe tool to use. if you've never used one, here is a quick introduction video

For detailed instructions se the manual or the saw Scroll Saw Manual

Because of the thin blade, using a scroll saw needs a delicate touch. If you push too hard, you will all too easily snap the blade. To cut a curved shape, feed the work with both hands, holding the wood flat against the saw's base while applying gentle forward pressure. The key is patience. Allow the work to feed through the saw blade slowly, without forcing it. If you begin to feel a greater level of resistance this will probably be due to a blunt blade.

A common mistake is to accidentally exert sideward pressure while feeding the wood through. If this begins to happen, relax the pressure on the wood by lessening the fingertip pressure. However, do not let go of the wood, just relax the pressure.

Blade Selection

Scroll saw blade sizes typically range from 1 to 12. Each blade size is designed to be used with different thicknesses of wood. The smaller the blade you can pick, the easier it is to cut delicate curves. The rough selection is as follows:

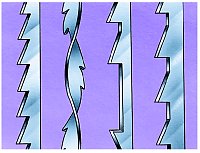

Scroll Blades (Shown on the left) are recommended for cutting thicker and harder material.

Spiral Blades (Shown 2nd from the left) blades are twisted so teeth point outward in every direction. A 360° capacity allows cutting in any direction without turning your work.

Reverse Blades (Shown 2nd from right) Teeth are pointed in both directions to give splinter free cutting on the top and bottom.

| Blade size | Hardwood thickness | Softwood Thickness |

|---|---|---|

| 1 to 2 | 1/4" | 1/4" |

| 3 to 4 | 1/2" | 3/4" |

| 5 to 6 | 1/4" to 3/4" | 1/4" to 1" |

| 7 to 9 | 1/4" to 1" | 1/4" to 2" |

| 10 to 12 | 3/4" to 2" | 3/4" to 2" |

Choosing the Right Blade for Your Scroll Saw (Video)

Technical Specification

| Cuts per Minute | 400-1,400 |

| Max Depth of Cut | 65mm |

| Net Weight | 29kg |

| Overall L x W x H | 620 x 285 x 310mm |

| Power | 120W |

| Rating | Trade |

| Stroke | 10 & 20mm |

| Table Size | 460 x 235mm |

| Table Tilt | 0-45° |

| Throat | 460mm(18") |

Tips & Tricks

- You must guide the wood into the blade SLOWLY, because the teeth are very small, and cut ONLY on the down stroke. If you push the wood into the blade too rapidly, you can easily break the blade.

- The teeth on the blade will wear out sooner or later. The blade must therefore be replaced often to obtain the best cutting results. A blade will stay sharp for half an hour to 2 hours of continuous running, depending on the material being cut.

- Be aware that the blade has a tendency to follow the grain of the wood. You can compensate for this by watching the grain carefully and guiding the wood past the saw blade.

- There is a jig and guide on the near right hand side of the bed to help you mount a blade in the bits. See picture to show where.

Maintenance

Every month inspect for damage and general wear and tear and asses state of stock blades and replace as needed.

Replacement blades Scroll Saw Blade Mixed Pack (60 blades) £15