Difference between revisions of "AutomatedStorageProposals"

m (→Proposal 4: Rotating Shelves) |

(→Proposal 4: Rotating Shelves) |

||

| Line 71: | Line 71: | ||

Boxes sit next to each other on shelf, in front of the rotating machine is a flat conveyer belt, and a solenoid or linear actuator to push boxes from shelf onto conveyer to take to the door, and back again. | Boxes sit next to each other on shelf, in front of the rotating machine is a flat conveyer belt, and a solenoid or linear actuator to push boxes from shelf onto conveyer to take to the door, and back again. | ||

| + | (Shelves would be as wide as the room is deep/wide depending if fewer larger shelves or a greater quantity of shorter shelves are desired) | ||

Advantages: | Advantages: | ||

Latest revision as of 22:22, 7 October 2012

These proposal are for a storage/retrieval system for the undermezzanine spaces, which are too low to walk into.

See Under mezzanine 1 for a rough diagram of one of the rooms.

Contents

General thoughts

A overhead system allows the whole floor area to be used for storage, while a floor-based one will take up some space for aisles.

Assuming we stack boxes more than one high, we'll want to keep empty stack slots in reach for "hanoi-ing" to get the lower boxes out. These empty slots need not be in fixed locations.

Interface to the door RFID would allow the system to start fetching your stuff while you're still arriving (even when you don't want it to).

Proposal 1: Gantry crane

A gantry runs along rails at the edges of the room, and a trolley runs along the gantry.

Advantages:

- Can be made from generic off-the-shelf hardware (angle iron, skateboard wheels/bearings)

- Floor is unmodified, apart from rails if using ground rails

- Nothing suspended from rafters, unless using overhead rails

- Potentially most efficient use of floor space so highest capacity

- Looks cool and industrial :)

Disadvantages:

- Complex control scheme will need lots of programming

- Many points of failure

Proposal 2: Serpentine suspended railway

A track runs in a serpentine or spiral pattern, slung under the ceiling, and a trolley runs along it. Mechanically simpler than the gantry, but needs more track, and will probably be slower. Could run out into the main room and bring things to workbenches.

Advantages:

- Simple control scheme

- Potentially fewer points of failure than gantry

Disadvantages:

- Needs strong curved track, may be difficult to source

- Less efficient use of floor space

- Lots of non-static load on rafters

Proposal 3: Floor-based carousel

A floor-mounted monorail or two-rail system in an oval layout. The railway is fully occupied with trolleys, so pushing one way will bring the next trolley around.

There are no aisles, so to get to your box, you need to push the carousel around until you get to your box. I'm imagining it manually powered.

A set of points next to the entrance allow removing the whole train out into the main G24 room. The main room won't have rails, so the trolleys will have to be able to run on a smooth floor.

Because of the step in the floor, we'll have to either make a false floor or run the rails up and down slopes.

Advantages:

- Mechanically very simple

- Safe in the event of power failure, nothing being lifted and can be manually operated

- No load on rafters

Disadvantages:

- Very inefficient use of floor space

- Requires one trolley per box, rather than just the crane

Proposal 4: Rotating Shelves

Shelves similar to this: http://www.youtube.com/watch?v=iS_DbPZB2ic (Inspired by Wall.E!)

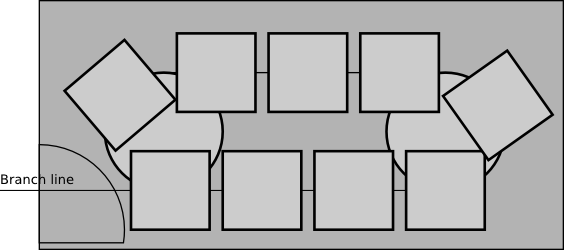

Boxes sit next to each other on shelf, in front of the rotating machine is a flat conveyer belt, and a solenoid or linear actuator to push boxes from shelf onto conveyer to take to the door, and back again. (Shelves would be as wide as the room is deep/wide depending if fewer larger shelves or a greater quantity of shorter shelves are desired)

Advantages:

- Mechanically fairly simple

- Safe in the event of power failure, nothing ever lifted.

- Fairly efficient space-wise.

- Fairly quick to "scroll" through shelves

Disadvantages:

- Side supports and chain assembly has to be pretty strong