Difference between revisions of "Equipment/3D Printer/UM2"

(→Ultimaker 2) |

|||

| Line 2: | Line 2: | ||

== Ultimaker 2 == | == Ultimaker 2 == | ||

| − | [[File: | + | |

| + | [[File:UltimakerWithLid.png|left]] | ||

The Ultimaker 2 is the newest FDM printer at MS. Its design is of a later generation than our [[Equipment/3D_Printer/Makerbot|Makerbot Replicator 2X]] and [[Equipment/3D_Printer/Up|UP!]]. The method of printing is almost identical but the implementation is more refined, so as a result the UM2 is expected to be faster, quieter and more reliable (in terms of both print outcome and maintenance). | The Ultimaker 2 is the newest FDM printer at MS. Its design is of a later generation than our [[Equipment/3D_Printer/Makerbot|Makerbot Replicator 2X]] and [[Equipment/3D_Printer/Up|UP!]]. The method of printing is almost identical but the implementation is more refined, so as a result the UM2 is expected to be faster, quieter and more reliable (in terms of both print outcome and maintenance). | ||

Revision as of 00:45, 23 November 2015

Class Red equipment: Do not use without specific training.

(More about equipment classes)

Contents

Ultimaker 2

The Ultimaker 2 is the newest FDM printer at MS. Its design is of a later generation than our Makerbot Replicator 2X and UP!. The method of printing is almost identical but the implementation is more refined, so as a result the UM2 is expected to be faster, quieter and more reliable (in terms of both print outcome and maintenance).

The manufacturer's product information page is here.

Owners

The Owners are those nominally in charge of the equipment, organising its maintenance, training others to use it, and generally being a point of contact.

The current Owners of the Ultimaker are:

- Mat Cook

- Paul Edgington

- Stephen Harrison

- Tom Parker

- Alberto Santos

- John Sidiropoulos

- Rob Voisey

If you have any questions, problems or concerns around the 3D printer, these are the people to contact.

Trainers

The Trainers are not in charge of maintaining equipment, but have been more thoroughly instructed in its use and can train others. They may run extra classes for recently trained learners.

The current Trainers for the Ultimaker are:

- Rob Voisey

- Paul Edgington

- Stephen Harrison

Training

YOU CAN ONLY USE THE ULTIMAKER IF YOU HAVE BEEN TRAINED

and have been added to the UM2 Trained Users list by one of the Owners or Trainers

To get trained on the Ultimaker and be added to the qualified user list, you will need to arrange for a training session with one of the owners.

If you'd like to arrange training, please see:

Note that persons who were previously trained on the Makerbot and UP! can attend a short conversion course to be signed off on the Ultimaker. Such members should not use the Ultimaker without having done this.

General Health and Safety

The Ultimaker is an expensive tool with a (small) risk of injury and fire, so is very important you know how to use it to avoid damaging yourself and the machine. The Ultimaker is a potentially dangerous piece of equipment which must only be operated by members who have received appropriate training and who take due care. The top things to always remember when using the Ultimaker are:

- ONLY USE THE ULTIMAKER IF YOU HAVE BEEN TRAINED

- ONLY USE THE ULTIMAKER IF YOU HAVE READ THE INSTRUCTIONS

As a responsible user, you should be very aware of the following risks and how to deal with them:

HEAD CRASH - incorrect calibration could cause the nozzle to hit the platen at job start

- Pay close to attention to the start of the job and be prepared to immediately abort the job if necessary

TRAPPING - The head and bed of the machine are moved by programs in the machine's memory.

- Be careful when near the machine, it will possibly move even if the PC is off

- Ensure you are familiar with the 'Pause' and 'Abort printing' functions on the Ultimaker so that in an emergency you can quickly halt printing.

BURN RISK - the platen on the printer is heated, and will reach temperatures up to 100C during a print run which could cause skin burns. The extrusion nozzle can reach temperatures of up to 260C. Do not touch either of these areas while printing, and keep the guard door securely closed while printing.

- Be careful when the machine has recently been used, especially when removing your print, as it may still be hot enough to burn

ELECTROCUTION - as with all mains powered devices there is a small risk of danger from exposed wires. Always do a manual check that the wiring is safe, no cores are exposed or wires trapped.

FUMES - In high concentrations ABS fumes may cause irritation. Do not spend extended periods over the printer whilst it is printing, and turn on the extractor/inlet fans of the main space when doing long print runs.

Plastics used in the printer

IMPORTANT The Ultimaker uses 2.85mm diameter filament. This must not be confused with the 1.75mm filament used by the other FDM printers at MS.

The Ultimaker can print with three different thermoplastics; PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene) and CPE. It is important to select the correct material on the printer control panel when loading filament as the printing parameters vary significantly.

PLA has a relatively low melting point and is capable of producing high quality prints at very fast speeds. It produces very few fumes and the odour from the melted material is actually quite pleasant. Prints are durable but not as strong as ABS, nonetheless this tends to be the material of choice for printing on the Ultimaker. PLA is available is a wide array of colours and finishes including metallic, glittery and stone effect.

ABS has a higher melting point than PLA and can be hard to get to stick to the platen. It generally requires a hot platen and raised/consistent ambient (which is why we have added a door and lid to the Ultimaker). Although more difficult to work with the resultant prints can be very strong.

CPE is a newer material with similar properties to ABS but without the fumes. This material needs to be printed at a high temperature which causes rapid wear of certain components in the extruder. For this reason we do not stock CPE and request that you contact an owner before using it.

The communal stock is kept in plastic boxes under the printers. Plastic filament is susceptible to absorption of moisture (i.e. it is hygroscopic) which causes it to expand and jam in the printer. For this reason the boxes have been fitted with a recirculating dehumidification system. It is important that the lids are removed for the shortest time possible, and that filament is returned to the box as quickly as possible when printing is complete. This will minimise wastage and reduce our costs.

Specific Safety Tips

There is a burn hazard from the nozzles and the heated platter, as mentioned above. The Ultimaker will display its current temperatures but you should not rely on this. The head may also move unexpectedly. Do not open the front door or place any part of your person inside the machine during or immediately prior to printing. ABS fumes over a long period may be harmful - if you feel light-headed take a break in a well ventilated area.

3D printing can be a lengthy process and you are not required to stand by the printer for the whole duration. You should, however, be present for the first few minutes, monitor your print using the webcam, and whenever possible be nearby to abort a failed print. If you spot the printer unattended with a failed print (this is obvious when it happens, with a rats nest of filament quickly forming) you are encouraged to abort the print on behalf of its creator.

Always switch the printer off at the back when you are finished.

Avoiding Damage to the Machine

The bed is made from glass. Use only plastic implements to remove your prints to minimise the risk of damaging the glass. Should you need to remove the bed for any reason (it is held in with clips) take care handling it and perform a bed levelling operation when you refit it.

The bed should generally be kept clean and free from dust. Wipe only with a lint free cloth (micro fibre cloths are provided) and avoid touching the build surface with your skin.

Using SD cards with the Ultimaker

The Ultimaker 2 does not yet support direct connection to a PC (this may come as a future upgrade) so you must copy your sliced (G-code) file to a DOS formatted SD card using the SD card writer attached to the PC, and then insert the card into the printer. We have found the Ultimaker to work with most modern cards. Some SD cards are available next to the printer - please remember to return them after use.

Remote access - Watch the printer via the Internet

You can view your Ultimaker print remotely, this allows you to check that the print hasn't failed and to monitor when the printer is finished before returning to the space to collect your print.

Navigate to http://makespace.ddns.net:8000 and select the Control tab.

- You do not need to be logged into OctoPrint to view the camera, anybody can view it (you may wish to cover the camera if you are printing sensitive projects).

- Internet Explorer doesn't appear to support the streaming video, Use Chrome or FireFox (untested with other browsers).

- It's can be a little slow to load and may be unresponsive when multiple people are connected.

- The url will only work outside of the Makespace network.

We use OctoPrint for the streaming, hopefully in future we will get OctoPrint more integrated with the Ultimaker so you can cancel your print remotely if you notice it has failed, however for now only viewing is possible.

Ultimaker Tips

Blocked nozzle when loading filament:

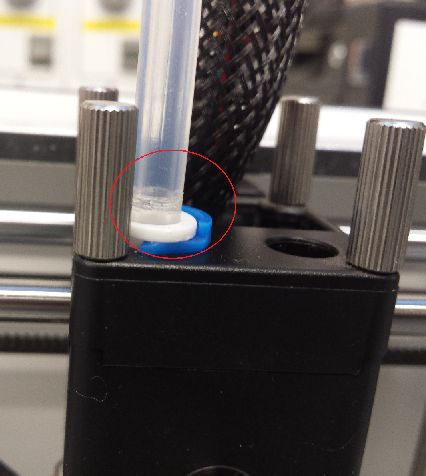

We've had a number of blockages reported when members are trying to load the filament. It appears that this is not actually the nozzle being blocked but the filament feed pipe not being fully homed into the extruder. If you have problems getting the filament to load check the feed pipe where it enters the extruder, if you notice a ring around the pipe above the white press fit fitting then the pipe has not been fitted correctly and the filament will hit the inside of the extruder before it even gets to the PTFE coupler.

Please report this to the Ultimaker Owners for fixing. You may try to resolve the issue by un-clipping the white push-fit fitting, pressing down and removing the pipe then carefully re-inserting it ensuring it is straight and fully homed. You should not see any rings around the pipe when it is fully homed and inspection of the middle of the extruder you should see the pipe butted up against the white PTFE coupler between the extruder body and nozzle.

This problem may be more apparent if you are using filament that is nearing the end of the reel where the filament becomes very curved. Try a different filament that is straighter.

General 3D printing Quality Tips

Check out the excellent 3D printing quality troubleshooting guide from Simplify 3D

Cure software tips

Download Ultimaker Cura Software

The Cura software remembers the previous settings used for a print and in some cases carries the advanced settings over to the basic option but doesn't display it (e.g. Brim). This can cause problems in a shared environment that the Ultimaker PC lives in as you may not get appropriate printing settings for your print if the last person adjusted them.

As the Ultimaker prints from an SD card and material settings are set on the printer itself you may prefer to install the Cura software on your own computer and save the file to an SD Card rather than using the Ultimaker PC to ensure you have settings that work best for your use case.

We are currently running 15.06 of the Cura software, this is a beta version and does not have many of the functions of the 15.04 version. For advanced users you may prefer 15.04 which has more functionality and includes advanced things such as repeat printing a design on the same plate spaced automatically so not to clash.

Filament not on a reel

Short lengths of filament are sold by many places rather than a full reel worth, we have a makespace laser cut acrylic reel that you can use to roll these onto and place on the back of the ultimaker. It has a larger diameter center to help. Currently this can be found in the cardboard box on the shelf above the Ultimaker.

Ultimaker Lid

Ultimaker do not provide a lid for the UM2 so we have a laser cut acrylic MakeSpace made one. Please be gentle with it!

If you have problems with the lid please report it to the Ultimaker Owners to allow us to improve the design and fix issues.

You should not need to remove the lid in normal day to day use. If you do remove it please ensure you replace it as it keeps dust from getting onto the plate (which messes up the print - Makespace is VERY dusty!) and helps keep the printing environment temperature better which should help improve your prints.

ABS Printing

The default setting for the Ultimaker bed is fairly low for ABS, we have found prints do not stick well at this temperature.

- When loading ABS check the bed temperature displayed on the screen when selecting the material

- A custom option is pre-defined for ABS with a higher bed temperature, we recommend around 110°C bed temperature for ABS.

- If you selected the wrong option when loading the filament the bed temperature can be adjusted when printing through the "Tune" menu option.

Ultimaker Community

Be sure to check out the Ultimaker Community site it is very active and a great resource.

Filament storage

We have a few dedicated filament storage boxes for the Ultimaker. These boxes are humidity controlled and have a Silica gel cartridge fitted to the lid to remove moisture. Yes, they are internet connected to allow the owners to monitor the humidity level and replace the silica gel when required. We aim to keep the humidity level below 15% in the box.

- Ensure the lid is kept closed on the filament storage boxes, leaving the lid off will degrade the silica gel quickly.

- Be sure to return the filament to the correct storage box after use to prevent undue exposure to moisture in the air which can ruin the filament.

- Do not store your own filament in the filament boxes. Personal filament should be stored in your own MakeSpace box.

- Keep your filament in a sealed plastic bag (or wrap with clingfilm).

- We have a supply of Silica gel on the shelf above the Ultimaker, you may wish to add a scoop or two into your bag to keep the moisture down. Use only the Orange colour silica gel. Green/Brown gel needs to be cooked to remove moisture.

- Do not eat the silica gel!!!

TO BE COMPLETED ASAP