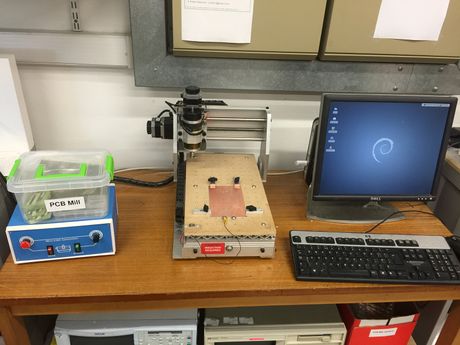

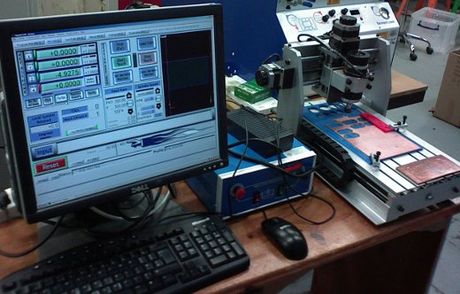

Equipment/PCB Mill

From Makespace

Revision as of 14:05, 3 February 2015 by Zoomzoomluke (Talk | contribs)

Class Red equipment: Do not use without specific training.

(More about equipment classes)

Contents

Summary

The PCB mill is a computer controlled (CNC) tool that can be used to cut the tracks for printed circuit boards (PCB). Training is required before members use the equipment because it is easy for users to damage themselves and the tool. Maximum travel is about 300mm in the Y direction, about 190mm in X, and 45mm in Z.

Machine is a generic 'CNC 3020', easily searchable on e.g. youtube for videos of use and configuration:

- Configuration with LinuxCNC video

ToDo before machine is available for use

Mandatory:

- Write instruction manual

- Write Risk assessment

- Document what is to be included in inductions

- Install and skim sacrificial bed

- Design and manufacture clamping arrangements

Desirable:

- Implement X and Y limit switches, and auto-zeroing.

- Sort tool chain for creating gcodes from PCB design files (Gerbers?)

- Build spring-loaded hockey puck for zeroing Z-axis, and implement zeroing procedure

Owners

- Alexis Mather

- Tom Oinn

- Robert Copcutt

- Mat Cook (tentative)

- Luke Twydell

Health and Safety

- Power supply to be switched off when changing tools.

- All cutting tools to be kept in their holders until they are required.

- Keep work area clear of waste material and offcuts.

- Check equipment for defects before each use to minimise the risk of possible electrical faults or fire.

- Carbon Dioxide extinguisher to be available for any electrical fires.

- Wear eye protection.

- Do not use outside of the workshop until an enclosure has been built.

Instructions

- Do not turn the black knobs on any of the three motors. Doing so may generate large voltages and damage the control board. Move only by command from the PC.

Tips & Tricks

Maintenance

Training

To get trained on the mill contact one of the owners.

Sessions are advertised on http://meetup.makespace.org

More about the training can be found at