Equipment/3D Printer

Class Red equipment: Do not use without specific training.

(More about equipment classes)

Contents

News

The new Makerbot Replicator 2X is the only printer currently working in the space. The UP! is out of action at the moment until it can be fixed (needs new electronic components).

Persons who were previously trained on the UP! are allowed to use the Makerbot after reading the manual. https://s3.amazonaws.com/downloads.makerbot.com/replicator2x/MakerBot_Replicator_2X_User_Manual.pdf

Please be aware of the following:

1. Windows software is not working; use an SD card, download the Linux software onto your laptop, or use the Linux box near the printer.

2. SD cards have to be PHYSICALLY 2GB or smaller (formatting a big card small doesn't work). They also have to be formatted in FAT16 (mostly Linux machines do this most easily). There is a small card lying around near the printer, free to use. It's labelled "MAKESPACE"; please don't absent-mindedly take it away!

3. The bed is covered with Kapton tape. DO NOT use a knife to remove models (hand-applied force should be plenty). If it's stuck, let the bed cool down and try again. And if you damage the tape, LET THE OWNERS KNOW!

Summary

This is our 3D printer. The 3-D printer is an UP! (a slightly older version of the device currently available).

We have a dedicated PC running win7 and UP! software. It can import STL design files from Google sketchup.

Using the UP! 3D Printer

The 3D printer is an excellent tool for either making small parts, or rapid prototyping. At the same time it is an expensive tool with a (small) risk of injury and fire, so is very important you know how to use it to avoid damaging yourself and the machine.

Owners

The Owners are those nominally in charge of the equipment, organising its maintenance, training others to use it, and generally being a point of contact.

The current Owners of the 3D printer are:

If you have any questions, problems or concerns around the 3D printer, these are the people to contact.

Trainers

The Trainers are not in charge of maintaing equipment, but have been more thoroughly instructed in its use and can train others. They may run extra classes for recently trained learners.

The current Trainers for the 3D printer are:

Training

YOU CAN ONLY USE THE 3D PRINTER IF YOU HAVE BEEN TRAINED

and have been added to the Trained Users list by one of the Owners

To get trained on the 3D Printer and be added to the qualified user list, you will need to arrange for a training session with one of the 3D Printer Owners.

If you'd like to arrange training, please see:

Health and Safety

The 3D printer is a potentially dangerous piece of equipment which must only be operated by members who have received appropriate training and who take due care. The top things to always remember when using the 3D printer are:

- ONLY USE THE 3D PRINTER IF YOU HAVE READ RELEVANT SAFETY NOTES

- ONLY USE THE 3D PRINTER IF YOU HAVE READ THE INSTRUCTIONS

- NEVER LEAVE THE PRINTER RUNNING UNATTENDED

As a responsible user, you should be very aware of the following risks and how to deal with them:

HEAD CRASH - incorrect calibration could cause the nozzle to hit the platen at job start

- Calibration must be carefully checked on each startup

TRAPPING - The head and bed of the machine are moved by programs in the machines memory.

- Be careful when near the machine, it will possibly move even if the PC is off

- Ensure you are familiar with the location of the power switch, to turn it off quickly should a problem occur

BURN RISK - the platen on the printer is heated, and will reach temperatures during a print run which could cause skin burns. Also a malfunction could cause this to overheat.

- Be careful when the machine is on, or has recently been used, to guard against burns

ELECTROCUTION - as with all mains powered devices there is a small risk of danger from exposed wires. Always do a manual check that the wiring is safe, no cores are exposed or wires trapped

Instructions

To use the printer you must familiarise yourself with the safety notes above and read the following instructions.

Power Up

- Give the machine a quick visual check. Make sure that there is nothing left on the platen. Remove the platen support piece from under the platen and gently lower it. Check the new material is feeding OK and the reel has enough on it

- Turn on the machine at the wall socket

- Initialise the machine - Open the 'Up!' software on the attached PC and double-click the software icon. Once it has loaded select '3D Print > Initialise' from the toolbar

Check calibration

This operation must be carried out to ensure the bed is level and has the height correct.

- Firstly find the current value of the nozzle height in the print dialog. This is only accessible once you have a design loaded, so load a model in (there should always be some in the '3D Printer Training' folder on the desktop) and then select 'Print' from the toolbar

- Note the printhead height from this dialog (currently 139.1) and press cancel to abort

- Go to the maintenance dialog (3D Print > Maintenance from toolbar) and set the head height to 20mm less than this height. Enter the value in the edit box and press 'To:' button

- Then move the bed closer to the expected value, in decreasing steps, until you reach the set height or the nozzle is going to hit the bed. If you reach the specified height (currently 139.1mm) there should just about be room to get a piece of paper between the nozzle and the bed.

- Once this has been checked you should drop the head to about '100' and then repeat the check at two other corners and the centre. When the platen is well below the head you can quickly go to the other locations using the FL/FR/NL/NR/Center buttons on the maintenance dialog

Load your Design

- Import your model - press the 'Open' icon on the ribbon bar

- Check the placing and size of your model - the printer software is quite clever, but it may not choose the best orientation of complex shapes. You want the largest flat surface on the bottom, so that less support material is required.

Download to the Printer

- When you are ready to print you can just press the 'Print' button on the ribbon bar

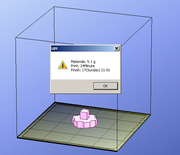

- Some calculations now take place and a popup box will appear with an estimate of how much material will be required as well as how long printing will take - please check 3D Printer Material Cost table and put your money in the honesty box

Worried whether there's enough filament left for your job? As a rule of thumb, one turn of the material drum is about 1g of material. - If you are happy then make a note of the material weight and check the cost against the table below

- Press 'OK' to proceed

- Watch the magic happen ...

DO NOT EVER LEAVE THE PRINTER UNATTENDED

Finishing

- When the part is finished the printer will make several beeps - but of course you will be watching so you will be expecting that

- DO NOT TOUCH THE PLATEN YET ! It is usually very hot, and it is best to give it a few minutes at least

- When it has cooled a little then with care you can peel the part away from the platen

- The 'raft' which was built to produce the part on should then separate with a little effort, and possibly careful peeling with a blade

Power Down

- Lower the platen to its rest position before turning off. Do this from the maintenance dialog (3D Print > Maintenance from the toolbar) and press 'To Bottom'

- Turn off the printer on the wall socket

- Gently lift the platen and put the platen support piece back underneath

- Shut down the PC and double check that everything is left in a safe and clean state for the next user

Cost

Currently we suggest to charge 10 pence per gram for prints, this is to cover the cost of material plus a little for wear and tear and other consumables. Please put your money into the blue labelled honesty box on the shelf above the printer.

Maintenance

The maintenance of the 3D printer is carried out by the Owners, with some basic maintenance being carried out by Users on every job.

Maintenance Schedule

Continuous Maintenance (Every job, done by all 3D Printer Users)

- Clean the platen of any plastic remnants

- Check the new material is feeding OK and the reel has enough on it

Basic Maintenance (Every week, done by 3D Printer Maintainers)

- Check the security and condition of all cabling

- Check the platen coating and re-paint any areas if necessary (green paint is in a pot with the printer)

Full Maintenance (Every 4 weeks, done by 3D Printer Maintainers)

- Tasks as per Basic Maintenance, plus

- Strip coating off platen and re-paint with a fresh coat

- Calibration check, if issues have been reported

Maintenance Log

Reactive Maintenance

- None

Regular Maintenance

- Week Number, Date, Type, Owner (Notes)

2013

- Week 08, February 18, Simon Stirley (Re-painted holes in platen coating)

- Week 09, February 25,

- Week 10, March 4,

- Week 11, March 11, Simon Stirley (checked wiring, posted safety notice, re-painted platen holes)

- Week 12, March 18,

- Week 13, March 25,

- Week 14, April 1,

Maintenance Shopping List

- TBD

Further Information

Manual

The manual is installed in the machine attached to the printer and also available here: Manual

Repairs

We expect to have to change the following parts for general maintenance:

- TBD

Maintenance and Spares:

- One UK supplier of consumables is Cool Components

Software

You can download Quickstart manual and latest driver software from pp3dp.

- Google SketchUp with STL plugin as below

- This plugin seems to work quite well. Use 'File/Export to DXF or STL' from Sketchup once you have installed it and select 'STL' as the last item in the type list when asked

- NetFabb repairs any incomplete STL files

- Meshlab is a good free program (Sourceforge) for visualising and modifying STL files

- OpenSCAD is a script-based modeller ('3D compiler'), well-suited for technical CAD (less so for artistic design)