Equipment/CNC Model Mill

Class Red equipment: Do not use without specific training.

(More about equipment classes)

A model mill for 3D subtractive prototyping, mould making, 3D scanning and PCB milling.

Contents

Summary

The MDX-40A is a full-featured CNC (computer numerical control) mill capable of cutting jeweler's wax, resins, chemical wood, acrylic and wood. It is ideal for quickly and easily creating high-quality prototypes, parts, models, and moulds for resin casting.

http://www.rolanddga.com/products/milling/mdx40/

- Capacity: 305 x 305 x 105mm

- Rate (X,Y): 50mm/sec

- Rate (Z): 30mm/sec

- Spindle Speed: 4500 to 15000rpm

- Resolution: 0.01mm

- Materials: Plastics (ABS, Delrin/Acetal, Nylon, Acrylic), tooling board, wood, and modeling wax, PCBs

- Includes scanning head

Here are some examples we've made on the Model Mill (please add a photo of yours any time you do a job!)

Michal Zalewski's Guerrilla guide to CNC machining, mold making, and resin casting has many tips on using a similar CNC mill and ideas for projects, with a particular focus on resin casting.

Using the Mill

Owners

The Owners are those who have volunteered to be in charge of the equipment, organising maintenance, training others to use it, and generally being a point of contact. The current Owners of this item are:

- Paul Osborn

- Robin Sterling

If you have any questions, problems or concerns around the Model Mill, please use the mailing list thread:

Training

You must must pass Makespace training to use this equipment.

Follow this link to find training https://classroom.google.com/u/1/c/MTIxMzI2MTc5ODY0

Health and Safety

The Model Mill is unlikely to hurt you, but you can easily hurt it without training so it must only be operated by members who have received appropriate training and who take due care. The top things to always remember when using the CNC Router are:

- ONLY USE THE MILL IF YOU ARE ON THE LIST OF TRAINED USERS

- NEVER LEAVE THE MILL RUNNING UNATTENDED

As a trained user, you should be very aware of the following risks and how to deal with them:

SHARP OBJECTS - The cutters used by the machine can be very sharp. Care should be taken when handling the cutters or working near the cutters such as when cleaning after use.

DUST - Ensure the machine is cleaned thoroughly after use.

Never use a pneumatic blower This machine is not compatible with a pneumatic blower. Cutting waste may get inside the machine and cause fire or electrical shock.

Instructions

Coordinate Systems

The main window in VPanel displays the present location of the tool as numerical values. Using these lets you perform manual feed accurately, which can be very convenient in tasks such as aligning the workpiece.

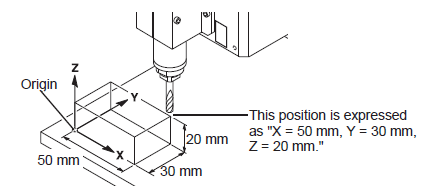

The numerical values that indicate the location of the tool are called "coordinates," and the starting point for the coordinates is called the "origin." The following figure shows a location that is shifted from the origin by 50 millimetres along the X-axis, 30 millimetres along the Y-axis, and 20 millimetres along the Z-axis. This X-axis distance is called the "X-axis coordinate" (or sometimes just the "X coordinate"), and the Y- and Z-axis distances are similarly called the "Y-axis coordinate" and the "Z-axis coordinate."

The distances from the origin for the respective axes to the tool are therefore the corresponding coordinate values.

It is possible to select the coordinate system that is used to display the tool location in VPanel. The selection made here only determines the method used to display coordinates.

With the actual origin point, you need to perform the setting individually for the coordinate system that is used with the cutting data. It is a good idea to leave the selection at "User Coordinate System" as this is the system used by most programs.

- User Coordinate System: This is a coordinate system in which the location of the origin point can be freely changed.

- Machine Coordinate System: This is a machine-specific coordinate system in which the location of the origin point is fixed and cannot be changed.

Pausing/Resuming/Quitting of Cutting

This operation pauses cutting. You perform it using the built-in panel. This also makes it possible to resume cutting at the paused position after an operation such as moving the tool to check the status of the workpiece.

Press the VIEW button during cutting. Rotation of the spindle stops, and the tool moves to the VIEW position. While movement of the tool and table is in progress, the VIEW lamp flashes, and after the movement is completed, the lamp lights up.

It is possible to open the front cover while the machine is paused. Before opening the front cover, make sure that the cutting operation stopped completely and that the VIEW lamp is lit.

Press and hold the VIEW button. The tool returns to the position where operation was paused, and cutting resumes. After the tool starts moving, the VIEW lamp flashes until cutting is resumed. When cutting is resumed, the VIEW lamp goes dark.

If you open the front cover while the operation is paused, close the front cover, then perform the operation to resume.

Tool Selection

Select a tool matched to the purpose. It's a good idea to use the tools selectively, according to the work process (such as rough cutting or finish cutting) and the design.

Cutters is an all-inclusive term used to describe the rotating cutting tools used. Cutters can be manufactured from high speed steel or carbide and are available in a variety of configurations for specific applications.

- End mill

- Straight end mill: The end cutting edge is flat-shaped. It is suitable for fashioning a flat surface or steps.

- Ball end mill: The end cutting edge is ball-shaped. It is suitable for fashioning a curved surface or waveform.

- Engraving cutter

- Character cutter: This tool is suitable for engraving in general with broad versatility. It is appropriate for character engraving on the plate.

- Parallel cutter: This cutter is suitable for engraving wide surfaces. This cutter enables engraving large characters and surface leveling (to flatten the surface of the material) of the table where the material is placed. Because both sides have a cutting blade, it is not possible to make a deep cut in the Z-axis direction.

Recovery of Operation from Emergency Stop or Emergency Shutdown

If an emergency stop or an emergency shutdown occurs during cutting, remove the tool and the workpiece from the machine. When the operation resumes, initialization is performed on the machine.

At this time, the tool and the workpiece may collide depending on the position in which the tool and workpiece stopped, which can cause damage to the machine while restarting.

Overrides

Using Overrides An override is a feature for adjusting the feed rate or spindle speed while cutting is in progress. This is useful when you want to change the feed rate or speed as you monitor the status of cutting. An override value is specified as a percentage. For example, when the command in the cutting data sent from the computer is for a speed of 5,000 rpm, specifying an override of 150% produces an actual speed of 7,500 rpm.

Cutting Speed Override This works on the tool movement speed of when the workpiece is being cut. The speed specified by the command in the cutting data is taken to be 100%.

Spindle Speed Override This works on the rotation speed of the spindle. The speed specified by the command in the cutting data is taken to be 100%. This is also effective when rotating the spindle during manual operations.

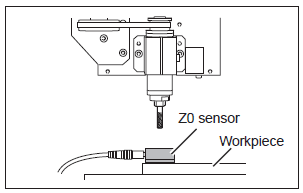

Setting the Z Origin Using the Z0 Sensor

A tool that has an extremely narrow tip may break when it touches the tool sensor depending on which tool is to be used.

1. Set the workpiece on the table, and place the Z0 sensor at the place where you want to set the Z origin on the workpiece. Face the surface of the Z0 sensor with no screw hole facing upward.

2. Use the VPanel feed button and move the tool to the position above the sensor.

3. Close the front cover.

4. Select "Set "Z Origin using sensor" and click Detect. The tool slowly descend until it contacts the sensor. When the tool rises and stops, the setting operation is complete.

Note: It is important the tool is electrically conductive from tip to shaft, and the sensor is clean. Failure to check will cause damage to the tool and sensor.

5. Remove the sensor from the workpiece to a location where it will not interfere with future cutting operations.

Software

VPanel

VPanel is a program to operate the modelling machine on the computer screen. It has functions to output cutting data, perform maintenance, and make various corrections. In addition, it displays error messages of the modelling machine.

ClickMill

ClickMILL is a program that lets you perform simple milling operations without a model (3D shape data). It allows you to perform drilling, chamfering and surface levelling and to cut flat panels to size in rectangular or circular shapes.

SRP Player

SRP Player imports a model (3D data in IGES, DXF [3D], and STL) and cuts a workpiece to transform it into the actual shape. It calculates the path of the blade that performs the cutting, and operates a cutting machine accordingly. The path of the blade is called the "tool path".

Surfacing and Drilling (Video)

Basic Introduction to SRP Player (Video)

Note: We do not have the Rotary axis or the tool changer show in some of these videos.

Cut2D

Cut2D is easy to use. The software automatically compensates for the cutter diameter and geometry when calculating toolpaths, so you simply select the shapes to machine and Cut2D takes care of the rest.

Cut2D opens CAD drawings and vector designs from most drawing packages and includes filters for the following industry standard file formats: DXF, DWG, EPS, AI & PDF files

Very simple projects can also be drawn directly in Cut2D.

Multiple designs can be imported and combined.

Cut2D allows the you to preview the calculated tool paths in a 3D window to see exactly what the machined part will look like.

Cut2D Tutorials These tutorials are very good and are your best resource for learning how to use this software.

CopperCAM

Manufacture's site for CopperCAM

An essential part of producing milled printed circuit boards is the ability to convert the Gerber photoplot files produced by most PCB layout tools to a format readable by CNC mill software to either isolate traces and pads or to "rub out" all copper on a board except traces and pads. You also need a tool to convert the common Excellon drill files to CNC language to drill the through holes and vias in the circuit board.

CopperCAM is a program for engraving and isolation routing. It only provides the Gerber and drill file conversion and does not provide any machine control. The exported files should be loaded and run via the vPanel software for download to the mill.

Tips & Tricks

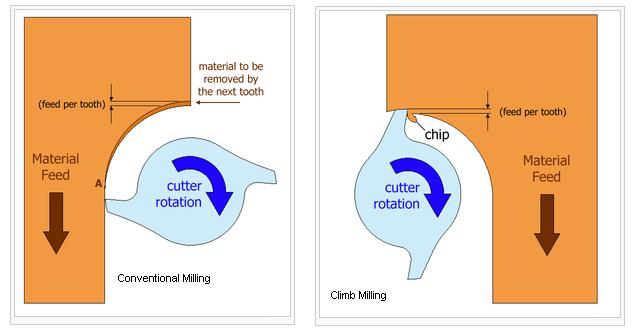

Conventional milling versus climb milling

A milling cutter can cut in two directions, sometimes known as conventional or up and climb or down.

Conventional milling (left): The chip thickness starts at zero thickness, and increases up to the maximum. The cut is so light at the beginning that the tool does not cut, but slides across the surface of the material, until sufficient pressure is built up and the tooth suddenly bites and begins to cut. In metals this deforms the material (at point A on the diagram, left), work hardening it, dulling the tool and leaves a poor finish on the material.

Climb milling (right): Each tooth engages the material at a definite point, and the width of the cut starts at the maximum and decreases to zero. The chips are disposed behind the cutter, leading to easier swarf removal. The tooth does not rub on the material, and so tool life may be longer. However, climb milling can apply larger loads to the machine, and so is not recommended for older milling machines, or machines which are not in good condition.

While climb cutting is the most prevalent method in metalworking and conventional cutting is the dominant method in woodworking, plastics routing is somewhere in between the two. There are usually significant differences between the finish on a climb cut part and a conventional cut part, and the degree of difference varies by plastic and cutter geometry. The only rule of thumb that can be offered is that most soft plastics (HDPE, UHMW, polypropylene, etc.) respond best to conventional cutting, while some harder materials (acrylic, polycarbonate, nylon) occasionally respond better to climb cutting.

The other factors when considering climb or conventional cutting are the aggressiveness of the cutter and part hold down. Climb cutting is a much more aggressive means of cutting and can chatter or move small parts that are not fixtured well. In most cases, soft chips that are difficult to extract from the cut are also more likely to weld to the climb-cut side rather than the conventional cut side. The best method of approach for most new materials is to run sample parts with both methods of cutting at the same feeds and speeds and make the determination from there.

Milling Wood

When milling wood, always set the path to raster and position your piece so that the tool is passing with the grain. If you use other settings then swarf builds up and can easily jam the tool. If you are cutting large areas of wood then you will need to be alert to the machine jamming due to build up of swarf, so don't go far. The machine does not work terribly well as a thicknesser, so consider using the bandsaw (although it doesn't like lime very much) or the CNC router. Clean the machine once you can see it getting really dusty, not at the end of the job, or it will take hours! Manually remove big chippings or Henry will choke on them.

Making PCBs

The Model Mill should not be used to machine metal. It isn't strong enough, and the HSS cutter provided by Makespace will be damaged by metal and fibreglass (e.g. FR4 PCBs) very quickly. However, if you are considered by the Owners to be an experienced and careful Mill User, then it is possible to make basic PCBs providing you use your own mill bed and cutters. For more information see the helpful guide here: PCB_milling

Making your own Base Plate

If you want to use screws to secure workpieces, or mounting holes etc you should make your own base to replace the public base installed in the mill. You can make a base plate easily using the large CNC Router. If you do not have access to that equipment, ask around for help, its a quick job. The base can be made from thick MDF or plywood. An example design file in SVG format is here: Media:model_mill_base.svg.zip

Stock Tools

Rough notes - siw

Cutter * Shaft * cutter Length * total length * type * material

- 3*3*3*75*ball*carbid Europa Tool Co.Ltd.

- 3*6*10*35*square*hss MR Tool

- 5*6*15*45*square*hss MR Tool

- 2*6*5*29*square*hss MR Tool

- 1*6*3*25*square*hss MR Tool

- 6*6*30*75*ball*carbid europa tool co ltd

- 6*6*20*45*square*hss MR Tool

- 4*6*12.5*40*square*hss MR Tool

- engraving tip 3.3*10mm sholder shaft 6mm total tool length 75, tip 0.2, 30deg carbid

- engraving tip 6*10mm sholder shat 6mm total tool length 45, tip 0.2, 30deg HSS

- engraving tip 1/4" 0.1 30deg 32 total

drills

- 1/4" 0.8mm * 8mm 38mm total

- 1/4" 0.9mm * 8mm 38mm total

Collets

- 1/8"

- 1/4"

- 6mm * 2

- 4mm

- 3mm

- 5mm

Maintenance

The maintenance of the Model Mill is carried out by the Owners, with some basic maintenance being carried out by Users on every job.

Maintenance Schedule

Continuous Maintenance (Every job, done by all Model Mill Users)

- Clean the mill with a 1" paint brush, remove as much dust from the spindle area as possible before vacuuming.

- Hover all the inside of the mill, and under it. Do not blow the dust, it goes everywhere!

- Clean any debris off bed and surround using soft brush

The machine should look like this after use!

Basic Maintenance (done by Model Mill Maintainers)

- The spindle unit and the belt are parts that wear out. The replacement cycle varies according to usage conditions, but as a general guide, you should replace them after every 2,000 hours of use. You can use VPanel to view the total working time of the spindle.

Maintenance Log

Installed on 21st March 2013.

Maintenance Shopping List

Further Information

Installation

Purchase

- MP-ROTO-MDX40AE (mill - £4,695)

- RL-ROTO-TS30SCAN (scanner head - £295)

- Selection of tooling (???)

- Sample selection of materials (???)

Repairs

Expected on-going maintenance costs are expected to be very low if maintained correctly. Two areas that will need watching for repair are:

- Spindle drive belt expected life 1000's of Hours (Supplier holds in stock) ~£10

- Spindle assembly (bearings fail) 10000 Hours MTBF (Supplier holds in stock) £195. It is suggest that when this starts to fail we buy a second spindle assembly and then repair the first, the bearings can be had for <£20.

Material & Tooling Suppliers

Material

Links below are only suggested sources, do shop around.

- Yellow Foam - Usually found lying around in the secure workshop

- Acrylic - Stock for sale by the laser cutter

- Model Board /Polyeurethane Foam (PU580 recommended for strength, but easy to work. PU240 is soft enough to mark with a fingernail).Easy Composites

- Modelling Foam - Can be marked with a finger nail, but resists a thumbprint Techsoft (not much stronger than the yellow foam)

- Wood - https://www.toolsandtimber.co.uk/ the lime blocks work well

Tools

- Huge range of tools, look for Milling Cutters, General Purpose - Cutwel

- Basic HSS and Carbide tools - Mr Tool

- Carbide Engraving Tools - http://www.ebay.co.uk/itm/130826028002

- PCB Router CNC NC Carbide RASP DIAMOND - http://www.ebay.co.uk/itm/360652609242

Related Machines

Here are other machines available in this class:

| Machine | URL | Price (UKP) | Size - X | Size - Y | Size - Z | Notes |

|---|---|---|---|---|---|---|

| iModela | link | 500 | 80 | 55 | 26 | |

| Heiz S400 | link | 1595 | 400 | 300 | 110 | |

| Modela Pro MDX-540 | link | 13995 | 500 | 400 | 155 | Plastic resin and light metal, 400 to 12,000 rpm, |

| Modela MDX-20 | link | 2799 | 200 | 150 | 60 | Wood, Plaster, Resin (modeling wax, styrenform), Chemical wood, Aluminum (A5052 according to JIS),Brass, 6500 rpm, includes scanning head |