Difference between revisions of "Equipment/CNC Model Mill"

m |

Perfectphase (Talk | contribs) (→Summary) |

||

| Line 30: | Line 30: | ||

File:Model_Mill_Job_1.jpg | File:Model_Mill_Job_1.jpg | ||

File:ModelMill_Gallery_1.jpg | File:ModelMill_Gallery_1.jpg | ||

| + | File:MDX_Mill_Gallery_20130407.jpg | ||

| + | File:MDX_Mill_Gallery_20130407_2.jpg | ||

| + | File:MDX_Mill_Gallery_20130406_1.jpg | ||

</gallery> | </gallery> | ||

Revision as of 00:59, 8 April 2013

THIS IS A NON-FINAL DRAFT VERSION

THE CONTENTS IS WORK IN PROGRESS AND LIKELY INCORRECT AND SHOULD BE IGNORED UNTIL THIS HEADER IS REMOVED

NO TRAINING IS CURRENTLY AVAIABLE

Equipment / CNC Model Mill

A model mill for 3D subtractive prototyping, 3D scanning and PCB milling.

Summary

The MDX-40A is a full-featured CNC (computer numerical control) mill capable of cutting jeweler's wax, resins, chemical wood, acrylic and wood. It is ideal for quickly and easily creating high-quality prototypes, parts and models.

http://www.rolanddga.com/products/milling/mdx40/

- Capacity: 305 x 305 x 105mm

- Rate (X,Y): 50mm/sec

- Rate (Z): 30mm/sec

- Spindle Speed: 4500 to 15000rpm

- Resolution: 0.01mm

- Materials: Plastics (ABS, Delrin/Acetal, Nylon, Acrylic), tooling board, wood, and modeling wax, PCBs

- Includes scanning head

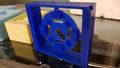

Here are some examples we've made on the Model Mill (please add a photo of yours any time you do a job!)

Using the Laser Cutter

Owners

The Owners are those who have volunteered to be in charge of the equipment, organising maintenance, training others to use it, and generally being a point of contact. The current Owners of this item are:

If you have any questions, problems or concerns around the laser cutter, please use the mailing list thread:

Training

YOU CAN ONLY USE THE MODEL MILL IF YOU HAVE BEEN TRAINED

and have been added to the Trained Users list by one of the Owners

To get trained on the model mill and be added to the qualified user list, you will need to arrange for a training session with one of the Model Mill Owners.

If you'd like to arrange training, please see:

Health and Safety

COMMING SOON

Instructions

COMMING SOON

Tips & Tricks

COMMING SOON

Maintenance

The maintenance of the Model Mill is carried out by the Owners, with some basic maintenance being carried out by Users on every job.

Maintenance Schedule

Continuous Maintenance (Every job, done by all Model Mill Users)

- Hover all the inside of the mill, and under it. Do not blow the dust, it goes everywhere!

- Clean the mill with a

- Clean any debris off laser bed and surround using soft brush

Basic Maintenance (done by Model Mill Maintainers)

- STUFF TO GO HERE

Maintenance Log

Installed on 21st March 2013.

Maintenance Shopping List

Further Information

Installation

Purchase

- MP-ROTO-MDX40AE (mill - £4,695)

- RL-ROTO-TS30SCAN (scanner head - £295)

- Selection of tooling (???)

- Sample selection of materials (???)

Repairs

Expected on-going maintenance costs are expected to be very low if maintained correctly. Two areas that will need watching for repair are:

- Spindle drive belt expected life 1000's of Hours (Supplier holds in stock) ~£10

- Spindle assembly (bearings fail) 10000 Hours MTBF (Supplier holds in stock) £195. It is suggest that when this starts to fail we buy a second spindle assembly and then repair the first, the bearings can be had for <£20.

Material Suppliers

Related Machines

Here are other machines available in this class:

| Machine | URL | Price (UKP) | Size - X | Size - Y | Size - Z | Notes |

| iModela | link | 500 | 80 | 55 | 26 | |

| Heiz S400 | link | 1595 | 400 | 300 | 110 | |

| Modela Pro MDX-540 | link | 13995 | 500 | 400 | 155 | Plastic resin and light metal, 400 to 12,000 rpm, |

| Modela MDX-20 | link | 2799 | 200 | 150 | 60 | Wood, Plaster, Resin (modeling wax, styrenform), Chemical wood, Aluminum (A5052 according to JIS),Brass, 6500 rpm, includes scanning head |