Difference between revisions of "Equipment/CNC Router"

Perfectphase (Talk | contribs) (→Instructions) |

Perfectphase (Talk | contribs) (→Setting the Z Origin Using the Z0 Sensor) |

||

| Line 90: | Line 90: | ||

Note: It is important the tool is electrically conductive from tip to shaft, and the sensor is clean. Failure to check will cause damage to the tool and sensor. | Note: It is important the tool is electrically conductive from tip to shaft, and the sensor is clean. Failure to check will cause damage to the tool and sensor. | ||

| − | + | 4. Remove the sensor from the workpiece to a location where it will not interfere with future cutting operations. | |

== Stock Tooling == | == Stock Tooling == | ||

Revision as of 02:16, 27 June 2013

Class Red equipment: Do not use without specific training.

(More about equipment classes)

Summary

A CNC router is a computer controlled shaping machine. These are related to the hand held router. Instead of hand held routing, the tool paths can be controlled via computer numerical control. It is a computer-controlled machine for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, and foams. It is one of many kinds of tools that have CNC variants. A CNC router is very similar in concept to a CNC milling machine. The CNC router is controlled by a computer. Coordinates are uploaded into the machine controller from a separate CAD program

- Capacity: 1200 x 1200 x 120mm

- Rate (X,Y): 6000mm/min (Max) 5000mm/min (Working)

- Rate (Z): 30mm/sec

- Spindle Speed: 4500 to 24000rpm

- Mechanical Precision: 0.01mm

- Spindle Power: 1.5KW Variable Speed, Water-cooled

- Blade Diameter: min 3.175mm, max 12.7mm

- Order Format: HPGL, G code, u00, mmg, plt

- Control System: DSP with USB connection

Here are some examples we've made on the CNC router (please add a photo of yours any time you do a job!)

Using the CNC Router

Owners

The Owners are those who have volunteered to be in charge of the equipment, organising maintenance, training others to use it, and generally being a point of contact. The current Owners of the CNC Router are:

- Stephen Woolhead

- Chris Abri

- Mark Mellors

- Dave Ansell

- David Bebb

- Simon Stirley

If you have any questions, problems or concerns around the CNC router, please use the mailing list thread:

Training

YOU CAN ONLY USE THE CNC ROUTER IF YOU HAVE BEEN TRAINED

and have been added to the Trained Users list by one of the Owners

To get trained on the CNC router and be added to the qualified user list, you will need to arrange for a training session with one of the Owners.

If you'd like to arrange training, please see:

Health and Safety

The CNC Router is a potentially dangerous piece of equipment which must only be operated by members who have received appropriate training and who take due care. The top things to always remember when using the CNC Router are:

- ONLY USE THE CNC ROUTER IF YOU ARE ON THE LIST OF TRAINED USERS

- NEVER LEAVE THE CNC ROUTER RUNNING UNATTENDED

As a trained user, you should be very aware of the following risks and how to deal with them:

FIRE - Cutting with the wrong settings could result in the material igniting.

TRAPPING - Stand clear of the machine while in motion.

DUST - Ensure extraction system is working.

NOISE - Ensure that you wear the correct PPE when working with the machine for prolonged periods.

Instructions

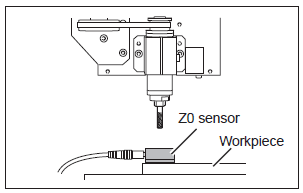

Setting the Z Origin Using the Z0 Sensor

A tool that has an extremely narrow tip may break when it touches the tool sensor depending on which tool is to be used.

1. Secure the workpiece on the bed, and place the Z0 sensor at the place where you want to set the Z origin on the workpiece. Face the surface of the Z0 sensor without the magnet facing upward.

2. Use the handset to move the tool to the position above the sensor.

3. On the handset press OK + 8(Z-0). The tool slowly descend until it contacts the sensor. When the tool rises and stops, the setting operation is complete.

Note: It is important the tool is electrically conductive from tip to shaft, and the sensor is clean. Failure to check will cause damage to the tool and sensor.

4. Remove the sensor from the workpiece to a location where it will not interfere with future cutting operations.

Stock Tooling

- 2.5mm square cutter - single flute

- 1/8" square cutter - single flute

- 1/8" ball cutter - 2 flute

- 6mm square cutter - 2 flute

- 6mm ball cutter - 2 flute

- engraver 0.2 30deg 1/8" 30mm length (8 of)

- engraver 0.8 30deg 1/8" 30mm length (2 of)

- 22mm 2 flute straight

- 90deg x 32mm VBit

Feeds & Speeds

Spindle speed quick reference

| 400Hz | 350Hz | 300Hz | 250Hz | 200Hz | 150Hz | |

|---|---|---|---|---|---|---|

| RPM | 24000 | 21000 | 18000 | 15000 | 12000 | 9000 |

Feed rate quick reference

| 100% | 75% | 66% | 50% | 33% | 25% |

|---|---|---|---|---|---|

| 6000 | 4500 | 3960 | 3000 | 1980 | 1500 |

| 5000 | 3750 | 3300 | 2500 | 1650 | 1250 |

| 4000 | 3000 | 2640 | 2000 | 1320 | 1000 |

| 3000 | 2250 | 1980 | 1500 | 990 | 750 |

| 2500 | 1875 | 1650 | 1250 | 825 | 625 |

| 2000 | 1500 | 1320 | 1000 | 660 | 500 |

| 1500 | 1125 | 990 | 750 | 495 | 375 |

| 1000 | 750 | 660 | 500 | 330 | 250 |

| 500 | 375 | 330 | 250 | 165 | 125 |

Sample feed rates

For working out feeds and speeds, recommend http://www.cnccookbook.com/CCGWizard.

The feeds and speeds below have been tested on our machine. The 3mm cutters were single flute carbide. 2 flute HSS cutters may require different settings to avoid breakages.

| MDF | 3mm deep | 6mm deep | 12mm deep |

|---|---|---|---|

| 3mm | 3000/24Krpm | 3000/24Krpm | 3000/24Krpm |

| 6mm | 3000/15Krpm | 2000/13Krpm | 1500/11Krpm |

| 22mm | 3000/5000rpm | 3000/5000rpm | 1500/4Krpm |

| Plywood | 3mm deep | 6mm deep | 12mm deep |

|---|---|---|---|

| 3mm | 2000/24Krpm | 2000/24Krpm | 2000/24Krpm |

| 6mm | 3000/15Krpm | 1500/15Krpm | 1000/11Krpm |

| 22mm | 3000/5Krpm | 3000/5Krpm | 1500/4Krpm |

Tips & Tricks

Maintenance

The maintenance of the CNC Router is carried out by the Owners, with some basic maintenance being carried out by Users on every job.

Maintenance Schedule

Maintenance Log

Installed on 9th May 2013.

Maintenance Shopping List

- Cutters

- Sacrificial Bed (1.2m x 1.2m 12mm MDF)

Further Information

Installation

Installed on 9th May 2013.

Purchase

Full Purchase, Delivery and Installation (£?????)