Difference between revisions of "Equipment/Laser Cutter"

| Line 388: | Line 388: | ||

* [http://www.leetro.com/english/down/LaserCut5.3%20Manual%20V1.6.pdf Manual] | * [http://www.leetro.com/english/down/LaserCut5.3%20Manual%20V1.6.pdf Manual] | ||

| − | [[/BitmapLaserEngraving | + | [[/BitmapLaserEngraving Bitmap engraving on the laser cutter]] |

== Installation == | == Installation == | ||

Revision as of 21:16, 10 December 2017

Class Red equipment: Do not use without specific training.

(More about equipment classes)

Summary

We have two LS 6090 PRO Laser Cutters. Each has a working area of 900mm by 600mm, and is powered by a 60w CO2 Water Cooled Laser Tube that can engrave and cut through materials such as wood, plastic, card, leather, fabrics, up to about 10-15mm thick (note, it can not cut metal). The laser cut is approximately 0.15mm wide, and a job can take a few seconds through to tens of minutes depending on material thickness and design complexity.

We have dedicated PCs running LaserCut 5.3 software to import, prepare and download jobs to the Laser Cutter. It can import various formats, with DXF being the most commonly used, so various software packages can be used to create your designs.

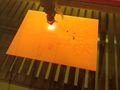

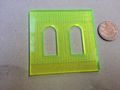

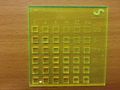

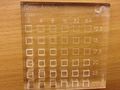

Here are some examples of laser jobs we've run (please add a photo of yours any time you do a job!)

Using the Laser Cutter

The laser cutter is a great way to easily produce accurate and complex 2D forms in various materials, and can be designed for with limited experience in various drawing or CAD applications. At the same time, it is an expensive tool with real risk of injury and fire, so is very important you know how to use it to avoid damaging yourself and the machine. You must only use the laser cutter if you have been trained, and if you are ever in any doubt about something, please ask for assistance.

Owners

The Owners are those who have volunteered to be in charge of the laser cutter, organising maintenance, responding to technical issues and generally being a point of contact. The current Owners of the Laser Cutter are:

- Mat Cook

- Diana Probst

- Owners who are a little less current, but may still be able to help:

Trainers

The Trainers are those who have volunteered to teach others to use the laser cutter and to promote good working practice. The current Trainers for the Laser Cutter are:

- Brian Starkey

- Stevan Wing

- Mat Cook

- Rob Voisey

- Miguel Morin

- David Barham

- Katy Marshall

- Currently slightly less frequent trainers are:

- Martin de Selincourt

- Simon Ford

- Nick Johnson

- Toby Moncaster

If you have any questions, problems or concerns around the laser cutter, please use the forum page:

For the old mailing list thread see here:

Training

YOU CAN ONLY USE THE LASER CUTTER IF YOU HAVE BEEN TRAINED

and have been added to the Trained Users list by one of the Owners

To get trained on the laser cutter and be added to the qualified user list, you will need to arrange for a training session with one of the Laser Cutter Owners.

If you'd like to arrange training, please see:

Health and Safety

The laser cutter is a potentially dangerous piece of equipment which must only be operated by members who have received appropriate training and who take due care. The top things to always remember when using the laser cutter are:

- ONLY USE THE LASER CUTTER IF YOU ARE ON THE LIST OF TRAINED USERS

- NEVER LEAVE THE LASER CUTTER RUNNING UNATTENDED

- KNOW WHAT TO DO IF A FIRE BREAKS OUT

- NEVER CUT MATERIALS THAT YOU DON'T KNOW ARE SAFE

As a trained user, you should be very aware of the following risks and how to deal with them:

FIRE (under normal operation) - Cutting at the wrong speed or the wrong power can result in the material igniting

- You must watch the cutter at all times and be prepared to abort the job if problems occur

- Small flashes of flame that don't hang around for a fraction of a second are acceptable, but any more is rare and not acceptable

- If a fire does take, this is the process you should follow (from minor to major):

- Press "pause" (the same button you started the job with) - This will turn the laser off so no more heat enters, and assuming the flame goes out, you can press "start" for the job to continue where it left off

- Open the lid - With the job paused, you can open the lid to blow out the flame. Again, it is possible to re-close the lid and continue where you left off

- Move the material from under the laser head assuming safe to do so (so it doesn't damage the optics; alternatively send the laser to home/datum), and smother with a spare sheet of material or blow out

- Use the workshop CO2 extinguisher to extinguish the flame

- You should also make a note in the log if any of this happens with associated materials and settings so we can keep track of any particular materials/settings we should look at

FIRE (abnormal operation) - If the head gets stuck or something else goes wrong, ignition could happen much more suddenly or intensely

- You must watch the cutter at all times and be prepared to abort the job if problems occur

- If the head gets trapped (e.g. tomb-stoning of a piece, mechanical failure) or any other problem occurs that causes or could cause fire, this is the process you should follow:

- Hit the emergency stop

- Open the lid and move the material from under the laser head assuming safe to do so (so it doesn't damage the optics)

- Blow out, smother with a spare sheet of material, or use the CO2 extinguisher to extinguish the flame as appropriate

- Ensure a Maintainer looks at the machine before it is brought back in to action if it is not obvious what went wrong and all is ok

- You should also make a note in the log if any of this happens with associated materials and settings so we can keep track of any particular materials/settings we should look at

FUMES - The laser cutting process will release different smoke and fumes depending on the material.

- Never cut PVC or a material you are not sure is safe. When PVC is heated it releases chlorine gas, this mixes with the moisture in the air and the result is hydrochloric acid which is toxic to humans and corrosive to machines.

- Ensure the filter is on and the cutter lid stays closed for a while after a job to allow the fumes to clear.

- If you are feeling strange, think the fume build up is too much, or for any other reason you are unsure, stop the job.

TRAPPING - The head and bed of the cutter can be moved by the front panel menu or programs in the machines memory.

- Be careful when working inside the cutting area or with the lid open not to trap hands, hair, clothing or anything else.

- Always check the machine for unexpected items that may have fallen in before closing the lid.

- Do not attempt to climb into the machine!

LASER BURNS/LIGHT - A 60W laser can do real damage.

- The laser should be safe within the confines of the machine, and cut-off automatically when the lid is open (although this should not be relied upon). The top window is safe to look through during a job, but do not attempt to interfere with these windows or the laser or in any way invent some way to look at the laser.

- Do not tamper with the laser cutter, or any interlocks. All side panels of the laser should always be closed and locked whilst the machine is plugged in.

- Do not put metal in the laser cutter.

Can I cut it?

If it's not on this list, the answer is "NO YOU CAN'T CUT IT AT MAKESPACE". Even if other people say it's ok. Bear in mind that we can't ventilate externally like other people can.

If it's something that isn't covered here, do ask on the forums and we'll look into it :)

- Woody things

- Wood: yes! (be careful of fire)

- Plywood: yes if it is "laser ply". Normal plywood has non-laser compatible glue

- MDF: no. Clogs up our filters and smells bad.

- LaserMDF: no. It produces perhaps 50% the gunk of MDF but still too much.

- Cork: yes, but it with a badly charred edge, and won't cut very deeply --- try cutting from the back of your sheet and using the cut to guide a craft knife / scalpel to make a neat cut through to the front.

- Plasticy things

- Acrylic / Perspex: yes!

- PVC/Vinyl: absolutely not. Produces chlorine.

- Silicone: we tried it with very limited success. A mm or two perhaps, anything else chars and doesn't cut.

- White Delrin/Acetal: yes with great care. Make sure filters running well. Don't open lid too quickly. Check for fumes and fire.

- Black Delrin/Acetal: no. contains carbon black which can be toxic.

- Teflon: no (it is toxic)

- Nylon: no (consult an owner)

- Polythene/polyethylene: no (consult an owner)

- Lexan/Polycarbonate: no (consult an owner)

- Polypropylene: yes just. You must clean the bed. It will cut up to about 2mm. It's not a great quality cut, but just about doable. Fire risk.

- GPPS / Polystyrene / HIPS in thin solid sheet form: maybe. ask owner to help. NO FOAM (it's highly flammable)

- Papery things

- Card/Paper: yes! (be careful of fire)

- Tissue: yes if super super really careful (be REALLY careful of fire, have emergency procedure in place before you start)

- Metally things

- Metal of any thickness doesn't cut. The surface can be engraved with a paint application. LMM6000 Surmark/Thermark has been tested and is suggested for use, but expensive. The owners suggest a speed of 800 and maximum power.

- Exotics

- Fibre glass: no (unknown resin, glass particles)

- Carbon Fibre: no

- Slate: engravable for good effect

Good list of info here: http://inventionstudio.gatech.edu/wiki/Laser_cutter (page disappeared, some time before 2016-12-12)

Very detailed cutting properties here: http://microfluidics.cnsi.ucsb.edu/tools/Trotec_laser_cutter/Synrad%20LaserProcessingGuide_Plastics.pdf

Instructions

To use the laser cutter, you must have been trained and have had your name added to the trained user list; these instructions are not a substitute for this training. See the training section to understand how you can become qualified to use the laser cutter.

Although not a requirement, it is recommended someone else trained is also present when using the laser cutter. Having two pairs of eyes helps avoid forgotten steps, allows for double checking, clarifications and discussions, and ensures a greater pool of experience is both present and being built up as the laser is used.

Power Up

Give the machine a quick visual check. Make sure that there is nothing left on the bed, the water reservoir of the chiller looks normal, and that the equipment has no obvious damage or signs of being out-of-action. If the bed looks like it has residue on it, give it a wipe with IPA and a cloth.

Turn on primary switch on the trunking marked 'Laser'. The air filter system to the right of the laser cutter should start as should the air pump and the chiller. It should power up, make a decent amount of noise, and the lights should indicate the filter is in good condition (i.e. no need for replacement).

Make sure the lid is closed. Turn on the laser using the key on the right hand side. The inspection lamp should come on, a satisfying hum start up, and the cutter go into doing its self-checks.

Before doing any job, the laser should be left to warm up for 4-5 mins. While the machine warms up, power on the adjacent PC and start the LaserCut application from the desktop. During this time the water temperature shown on the chiller should drop from ambient temperature to the usual setting of 18C.

Load your Design

The PC software has an import facility (file > import) which seems to be happy taking AutoCAD 2004 DXF files and other formats. The workspace of the laser bed is represented as the workarea in the LaserCut software. If the import doesn't do what you want size-wise, you can select the whole image and then use the 'size' command from the drop down menu to set the dimension you want. Clicking on the three dots ... symbol will adjust the other axis in the same proportion (keeping the aspect ratio fixed). Selecting the 'centre on bed' option will locate your imported drawing on the centre of the machine's cutting bed.

Assign Settings to Colours

Each part of your drawing that is assigned a different colour can have a different cut action assigned. Each colour will appear on the menu on the right hand side of the screen with numbers related to power and speed of the laser which will be used for the colour.

The main options are to Cut (line) or Engrave (raster fill). A marking on the material is a Cut. For each material and cutting depth required, a corresponding speed and power must be entered. The handbook provided with the machine gives suggested values for various materials but these should be considered as a starting point for a test. See the Power and Speed Settings section for our guidelines and experiences for these settings.

Download to the Cutter

Your drawing will feature a blue dot which represents the starting point of the laser; this is by default on the top right corner. In general, you will want to use "immediate" mode, which means this point represents wherever the laser is positioned when you start the job. You can also run the job in absolute mode by unchecking the box, making the job use absolute positioning on the workspace.

To download, select Download and Download Current; the download option will by default call the file on the laser cutter 'LASER'.

Set the Focus

Before each job, the focus needs to be checked and set by adjusting the height of the bed, and thus the work piece, from the lens. The critical dimension here is 41mm and several gauges made of perspex will be left around the machine. This gauge needs to be a fit between the top surface of the material you intend to cut and the white plastic 'flap' on the lens piece. The height of the table is adjusted using the UP and DOWN buttons. Failure to set the distance correctly will result in an out of focus laser and much bigger (but lower powered) cut line. Always ensure there is clearance between the material and laser head before the head moves.

Aligning and Testing the Job

The cutter's menu will show the most recent downloaded file highlighted. Pressing the 'test' button will make the head travel along the square maximum extends of the cuts. This shows you that you have the material in the right place, and you have enough of it! You can do this repeatedly, moving the work piece by hand or the laser head using the arrow keys (after hitting ESC), until you are confident you have things where you want them.

Cut the Job

When happy with the location of the material, close the lid and press 'start' to start the cutter. Watch the head and at least at first be prepared to press the 'stop' button immediately if you find you are burning massive holes in your work piece! This goes back to doing some tests on a sample of your material and making sure you are happy with the cut speeds and power you have selected. You should stay near the cutter at all times and be prepared to pause it or stop it in the event of fire.

DO NOT EVER LEAVE THE CUTTER UNATTENDED

Finishing

The end of the job is signified by a beep. Waiting a few moments for the exhaust pump to clear any remaining smoke is a good idea, especially with wood, and will limit the build up of smells in the rest of the workshop. Remove your work piece, ensuring that all parts are cleared from the bed of the machine.

Power Down

The cutter is turned off using the key switch, then the air filtering system with the green rocker switch. Shut down the PC and double check that everything is left in a safe state for the next user.

Clean the bed of debris using the soft brush, then wipe down the bed using IPA and a cloth.

If you have been cutting particularly 'dirty' materials, most notable MDF and Ply which leave a sticky residue then you will need to use the course side of one of the oven pads and lots of 'elbow grease'. Residue on the bed can impact the next persons' job so please make the effort to clean up and leave the cutter as you would wish to find it.

Go away excited by what you can make and come back with lots more drawings!

Power and Speed Settings

In due time we will try to build up a large sample stock of materials and record the values which work best. Here are the sample material tests we have so far:

Settings to get you started:

- 3mm Acrylic: Speed 12, Power 100, Corner power 100

- 5mm Acrylic: Speed 6, Power 100, Corner power 100

- Acrylic shallow cut: Speed 30, power 50, corner power 50

- Etching acrylic: Speed 400, Power 50, Spacing 0.05

To make your own material test, a test grid can be downloaded here: Media:Test grid.zip

- 3mm Delrin: Speed 10, Power 100, Corner power 100

- 5mm Delrin: Speed 4, Power 100, Corner power 100

- 6mm Delrin: speed 3, Power 100, Corner power 100

Tips & Tricks

- If the laser cutter's user interface does not seem to respond/do what you want, hit "ESC" to return to 'normal mode'.

- The opaque white acrylic needs slightly stronger settings for surface cuts as they are not as visible as in the transparent acrylic (i.e., for similar effect you need a deeper cut). Otherwise seems to cut equivalently to transparent acrylics.

- If you want a tight fit of pieces or very accurate sizing, keep in mind that the laser beam has a width of just over 0.1 mm (maybe 0.11 or 0.12 mm). So all exterior cut lines should be offset by 0.05 mm; you can do this very easily in the LaserCutter Software with the "Offset" tool (units are in mm, so enter '0.05' and select 'Outer').

- The DXF file format stores values only (not values and units). The internal units in the LaserCutter are in mm. If you set your document's units to mm in the exporting CAD system it should work fine, but generally it is a good idea to have a piece of geometry of known length, e.g. a line 100mm long, or a box of known size around your design. This makes adjusting the scaling a lot easier.

- If you want to export a DXF from Inkscape (which is a great, free vector drawing package), then make sure you do "Object to path" from the Path menu for the whole object and then during the export stage, untick both options for type of export. Choose mm as your unit.

- There's now a page to help with Inkscape and our laser at Equipment/Laser_Cutter_Inkscape

- If the jog buttons (arrow keys moving the laser head around) are only moving the head in small single steps rather than moving it continuously, make sure that the jog step size is set to 0.0mm in the Jog Settings section of the menu.

Material Usage

You want to use as little material as possible to save money, we want you to use as little material as possible to reduce re-stocking burden and wastage. There's a neat tool you can use for packing SVG files into small spaces, find it here: http://svgnest.com/

Fixing up a job that went wrong

If you messed up a job and, for example, some cut lines weren't cut, you might try to run the job again after recolouring all of the lines except the ones that didn't cut. You can then deselect those lines for output in the Cut/Engrave window on the top right of the Lasercut Interface, and this will keep your positioning.

If your head has moved, you can try setting some lines to power 1, which should not cut anything, but allows you to see where the head is travelling.

Fixing strange issues

Jaws has a FAQ on the desktop of her PC, with more useful hints, tricks, and solutions.

- Etching doesn't work

- Lines are not closed. LaserCut usually warns you about this. Ctrl-a to select all, then Tools->Unite Lines (0.001 should be fine).

- Two copies on top of each other. Copies on top of each other "cancel out" any etching. Delete one copy.

- Test with Menu->Laser->Simulate

- LaserCut will not download to the laser cutter

- Check laser cutter isn't in a paused state

- Restart LaserCut on the PC. (We've not had any usb issues nor needed to restart the laser since upgrading the PC summer 2014).

- Laser cuts things out 2+ times

- Check you don't have two copies loaded on top of each other

- Check it's not set to cut multiple times in LaserCut (this setting is right of the Cut/Engrave/Speed/Power settings)

- Check the laser front panel says "001" at the bottom. If not, press right arrow until the number is highlighted, then down to adjust back to 1, then press return.

- Laser will only cut at the top right of the bed

- Download again with Immediate Mode ticked

- On laser panel, press return (I think?) then right twice (should select the bottom left option), then press return (I think).

- You Hit Emergency stop

- E-M button needs twisting to re-activate

- If that fails - check the circuit breaker inside. From the back of the machine, you want to open the lower flap on the left side, which should be unlocked. Near to the back, there is a breaker board. Flip the flippy bit.

Material Stock

For the stock we hold, please see the Laser cutter stock page.

Maintenance

The maintenance of the Laser Cutter is carried out by the Owners, with some basic maintenance being carried out by Users on every job.

Maintenance Schedule

Continuous Maintenance (Every job, done by all Laser Cutter Users)

- Clean the laser bed with IPA and cloth or Swarfega wipes

- Clean any debris off laser bed and surround using soft brush

Basic Maintenance (Every week, done by Laser Cutter Maintainers)

- Clean the laser lens with IPA and cotton buds

- Oil the 3 runners with 3-in-one light oil

- Thoroughly clean the laser bed with IPA and cloth

- Check the water level in the cooling tank

- Clean and remove debris from the machine base and catchment drawer

Full Maintenance (Every 4 weeks, done by Laser Cutter Maintainers)

- Check the water is clean in the cooling tank (i.e. no contamination/organic build up)

- Check filter unit for filter renewal

- Oil the 4 rise and fall lead screws with 3-in-one light oil

- Check mirrors and clean with a disposable sachet lens cleaner cloth (only if needed, mirror coatings are delicate)

- Work through mirror alignment procedure to check alignment of mirrors

Maintenance Log

For full log, see laser cutter wall sheet

For specific instructions and owner hints and tips see Owner Hints and Tricks.

Filter Changes

- Jaws: 10 Feb to 22 June 2016, slightly under 5 months, and falling

- Betsy: Freshest data currently in filter unit, gave up on 24th of June

Reactive Maintenance

- 15th Jan 2013, Simon Ford: Laser cutter not powering up, with switching on via key gives no activity whatsoever. No recollection of it cutting out during a job (Alexis), so assume it just stopped turning on at some point. Filter box and power sockets confirmed OK. Diagnosis: RCD in right back panel of Laser reset to off, no obvious reason why. Switching back on brought everything back to life OK.

- 22nd, Simon Ford; 29th, Nicholas - same again.

- Apr 2014, Mat Cook and Diana Probst: after previous changing of chiller water (Roger et al) the pump was complaining of lack of flow. Changed water and filtered, removed small blockage from rubber hose on laser tube.

- 16 Apr 2014, Toby and Diana: changed laser tube, refilled chiller. Laser cutter fully working.

- 25 Oct 2014, Mat and Diana mended lid spring brace. Cutter working fully.

Regular Maintenance

- Week Number, Date, Type, Owner (Notes)

2013

- January 7, Full, Chris @ HPCLaser

- January 14, Basic, Simon Ford

- January 21, Full, Simon Ford (running better than new :)

- ...various maintenance events happened...

- April 5th, Full, Simon Ford

- July 1st, Full, David Barham (realigned mirrors)

- July 15th, installed chiller

2014

- 16 Apr 2014, mirror alignment and optics checked after re-installation of tube. All fine. Toby and Diana.

- 19 May 2014, mirrors cleaned, earthing wire on lid tightened. Diana (and Mat's screwdriver)

- 21 May 2014, cleaned lens with Mat Cook. Diana

- 02 Jun 2014, removed and cleaned laser bed

- 14 Sep 2014, cleaned lens and mirrors, realigned. Diana and Brian Starkey

- 30 Jun 2014 Fitted microswitches in series with the magnetic "lid closed" detector.

- ??? 2014 "Jaws" Second laser cutter acquired

- ??? 2014 Fitted microswitch to Jaws

Maintenance Shopping List

- 3-in-one light oil

- Cotton Buds

- Lens cleaner sachets

- Soft paint/cleaning brush

- Thermometer for water tank

- Hand held CO2 extinguisher

Further Information

LaserCut 5.3

/BitmapLaserEngraving Bitmap engraving on the laser cutter

Installation

Purchase

Full Purchase, Delivery and Installation (£6865.00+vat = £8238.00)

- LS 6090 PRO Laser engraving and cutting machine, 600mm by 900mm 60W (£5250.00+vat)

- Laser Fume Filter (£1250.00+vat)

- Delivery (£190+vat)

- Installation/Training (£175+vat)

Repairs

We expect to have to change the following parts for general maintenance:

- The laser tube (guess every 6-12 months)

- The filter (guess every 3-6 months)

- The optics (guess every 6-12 months)

Maintenance and Spares:

- 60 watt C02 laser tube (£275.00+vat)

- 50 mm Focus Meniscus Lens (£75.00+vat)

- Estimate for Call Out (£200.00)